Innovative Solution for

India’s Top Telecom Player

HFCL’s 1F Outdoor Round Drop Cable

for FTTx Deployment

Case Study

Highlights

Developed and tested

4 prototypes

to achieve the final

design

6X increase

in crush resistance

for enhanced durability

Filed a patent for the

innovative

design

Conducted extensive testing under 10 different

conditions with varying sample temperatures

Conducted extensive testing under 10 different conditions with varying sample temperatures

Successfully commercialized the design, deploying

1000s of kilometers of cable

Successfully commercialized the design, deploying 1000s of kilometers of cable

Background

India's leading telecom operator faced significant challenges with their existing aerial round drop cables. High failure rates, especially in North India and Kashmir, were attributed to environmental factors and regional activities

Customer’s Overview

The customer, a major telecom operator in India, required a solution to address the failure rates of their existing drop cables. The cables were susceptible to damage from kite flying activities in North India, which could tear the outer jacket and expose the inner components

Excessive sagging due to heavy snowfall in Kashmir, leading to power loss and disrupted customer connections

HFCL embarked on developing a robust 1F aerial round drop cable designed for both indoor and outdoor applications, aimed at withstanding harsh environmental conditions and ensuring reliable performance in FTTx networks.

Applications of Our 1F Aerial Round

According to Data Bridge Market Research, the FTTx market is projected to grow at a CAGR of 8.62% from 2022 to 2029, reaching an estimated value of $1.34 billion. HFCL’s innovative 1F Outdoor Round Drop Cable is well-positioned to meet this increasing demand.

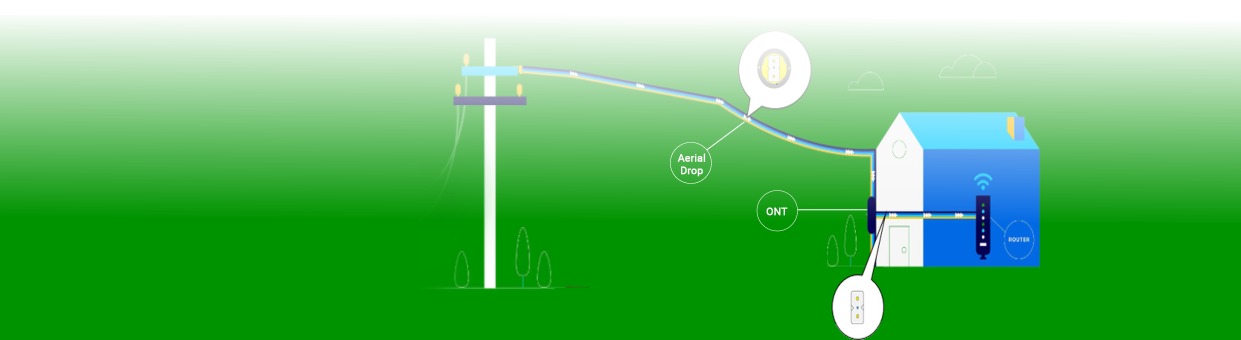

Designed for both indoor and outdoor use, this cable can be mounted as an aerial cable between poles, secured at the ends with clamps.

When entering a building or house, the outer jacket is stripped off, and the inner core—meeting all indoor cable requirements—is connected to the router. This design ensures a seamless transition and reliable performance from the external environment to indoor setups.

Challenges Faced

Damage from the ‘Manjha’ Thread

The cable needed to withstand damage from glass-impregnated strings (manjha thread) used in kite flying. This posed a significant threat to the cable's outer jacket, which, if compromised, could lead to exposure of the inner core, signal degradation, increased maintenance costs, and disrupted service for end customers.

Cable Sagging due to Snow Accumulation

For overhanging applications, the cable must endure short-term loads from accumulated snow or ice on its outer surface, which can cause sagging and potential breakage. Even a slight load on the sensitive inner core could compromise optical performance, risking frequent service interruptions and eroding customer trust.

Environmental Temperature Intolerance

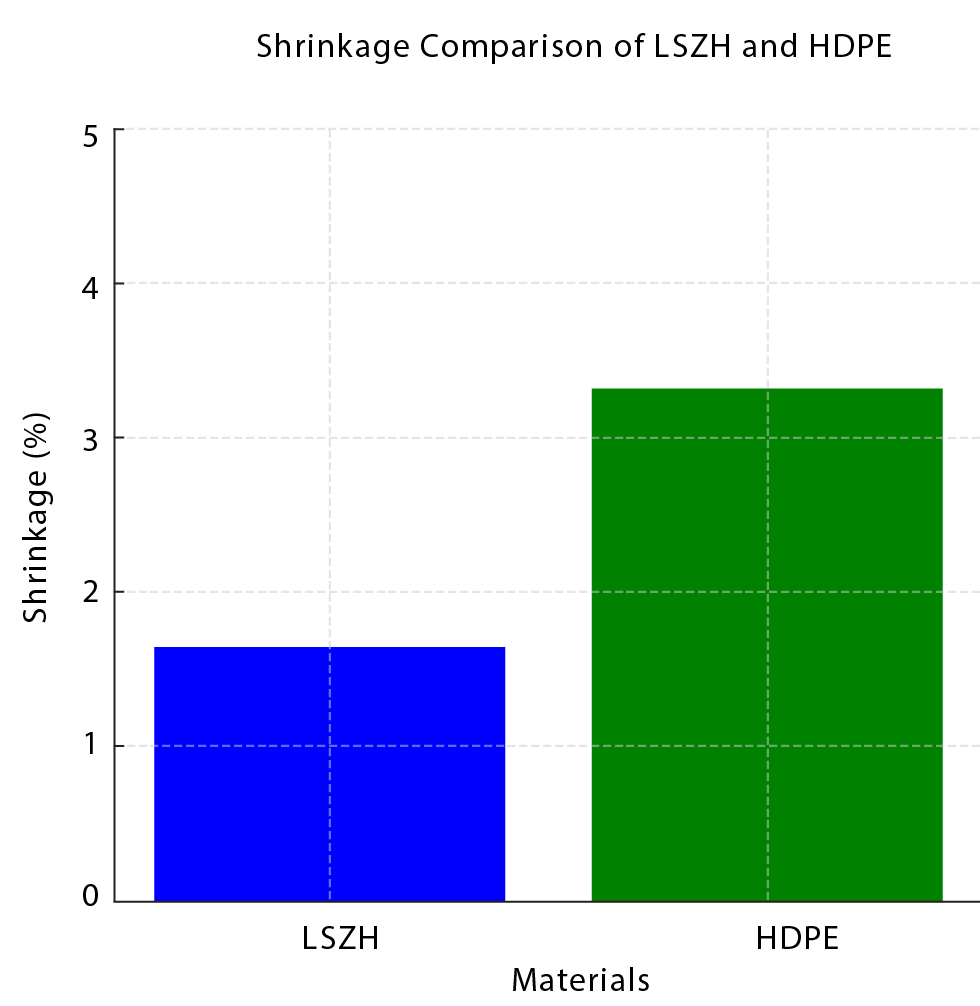

Designing a universal drop cable suitable for regions with temperatures ranging from -20°C to +70°C posed challenges due to the shrinkage effects of outer jacket material. Temperature variations could cause materials to expand and contract, leading to jacket shrinkage or brittleness, compromising the cable's durability and performance.

Maintaining Flexibility and Strength

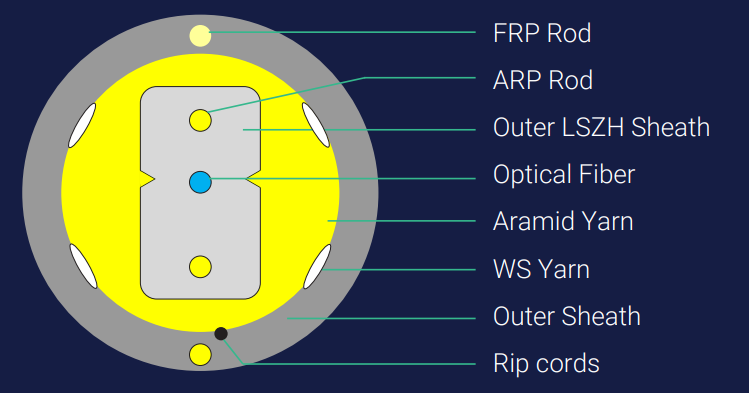

Embedding FRP rods within the jacket thickness to mitigate outer jacket shrinkage presented challenges in material selection. Balancing flexibility for indoor/outdoor use, particularly around building corners, was crucial. The inner core already incorporated ARP (Aramid Reinforced Plastic) rods with a flexural modulus lower than FRP (Glass Fiber Reinforced Plastic) rods, adding complexity to the design process

HFCL’s Approach to the Challenges

-

1

Choosing the Right Material with Enhanced Tear Resistance

The original design used LSZH material for the outer jacket, a material commonly used for drop cable jacketing due to its minimal sheath shrinkage and low coefficient of thermal expansion (CTE). The new design replaced LSZH with High-Density Polyethylene (HDPE) for its superior tear resistance and durability. To address HDPE's higher CTE and higher shrinkage at low temperatures, Fiber Reinforced Plastic (FRP) rods were integrated within the jacket. By embedding FRP rods in the cable jacket, we effectively controlled the shrinkage effect caused by temperature fluctuations. This integration not only mitigates shrinkage but also significantly enhances tear resistance, ensuring the cable can endure the harsh impact of manjha threads.

-

2

Improved Tensile Strength

Aerial drop cables must endure both short-term and long-term tensile loads during installation and after deployment. During our laboratory tests, we observed potential issues with jacket elongation. To address this, we applied a specialized adhesive coating, known as Ethylene Acrylic Acid (EAA), to the FRP rods embedded in the cable jacket. This coating ensures that the FRP rods bond securely to the jacket, effectively reducing elongation and providing a more robust solution to this challenge

-

3

Increased Crush Resistance

Our initial design complied with 500N, a standard for all drop cables. After the redesign, the new version now withstands up to 3000N, a 6X increase, safeguarding the sensitive inner core from physical damage and ensuring that optical performance remains uncompromised

-

4

Optimized Flexibility with Selected Strength Members

The cable is designed for both indoor and outdoor use. For indoor applications, it must navigate bends and sharp corners easily while adhering to the cable’s minimum bend radius. Achieving this required carefully selecting the size of the FRP (Fiber Reinforced Plastic) rods to match the flexural modulus of the ARP (Aramid-Reinforced Plastics) rods, ensuring optimal flexibility. Combining embedded ARP rods in the inner core and FRP rods in the outer jacket provides the required flexibility for indoor use and the strength needed for outdoor conditions

Result

These efforts culminated in the development of HFCL's 1F Outdoor Round Drop Cable for FTTx Networks focusing on indoor and outdoor applications.

Prototypes and Testing

We developed the final prototype after multiple design iterations and subjected it to testing under ten conditions with varying sample temperatures.

The cable's universal design was validated, making it suitable for deployment across different regions globally.

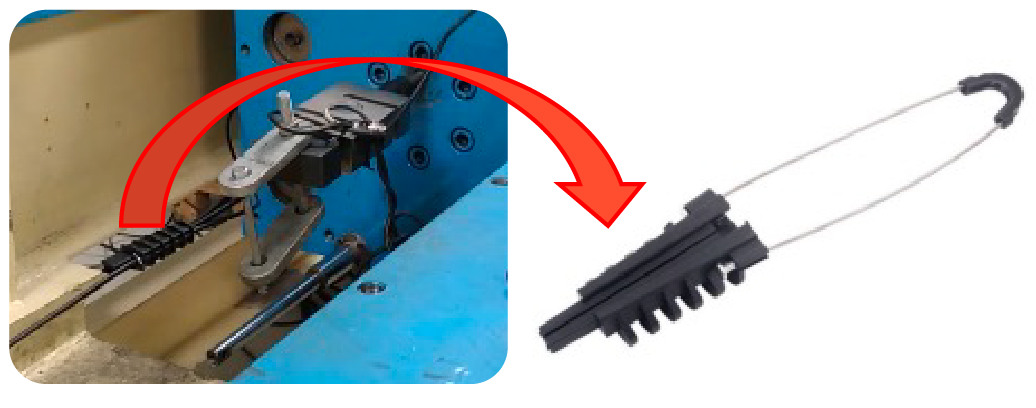

Testing at an external facility (Aerial Cable Clamp Manufacturer's Laboratory) confirmed the new design's compatibility with the clamps and demonstrated that it met all required standards.

Significant Supply of the New Design

Supplied 1000s of kilometers of the new cable design to customers, demonstrating reliable performance and significantly reduced failure rates

Conclusion

HFCL's innovative approach led to the development of a robust 1F Outdoor Round Drop Cable, tailored for both indoor and outdoor applications in challenging environments. By addressing specific regional problems and widely variable environmental conditions, HFCL provided a reliable solution that enhanced the performance and durability of a customer’s FTTx networks. This successful project showcases HFCL's commitment to delivering high-quality, customer-centric solutions

HFCL is a leading technology company specializing in creating digital networks for telcos, enterprises, and governments. Over the years, HFCL has emerged as a trusted partner offering sustainable high-tech solutions with a commitment to providing the latest technology products to its customers. Our strong R&D expertise coupled with our global system integration services and decades of experience in fiber optics enable us to deliver innovative digital network solutions required for the most advanced networks.

The company’s in-house R&D Centres located at Gurgaon and Bengaluru along with invested R&D houses and other R&D collaborators at different locations in India and abroad, innovate a futuristic range of technology products and solutions. HFCL has developed capabilities to provide premium quality Optical Fiber and Optical Fiber Cables, state-of-the-art telecom products including 5G Radio Access Network (RAN) products, 5G Transport Products, Wi-Fi Systems (Wi-Fi 6, Wi-Fi 7), Unlicensed Band Radios, Switches, Routers and Software Defined Radios.

The company has state-of-the-art Optical Fiber and Optical Fiber Cable manufacturing plants in Hyderabad, an Optical Fiber Cable manufacturing plant in Goa, and its subsidiary HTL Limited in Chennai.

We are a partner of choice for our customers across India, Europe, Asia Pacific, the Middle East, Africa, and the USA. Our commitment to quality and environmental sustainability inspires us to innovate solutions for the ever-evolving customer needs.