Innovation in Every

Fiber

HFCL’s Award-winning Fiber

144-1728F Compact Armored IBR OFC

Case Study

Highlights

36% faster mid-span access

for quicker customer connections

36% faster mid-span access for quicker customer connections

Up to 43%

lighter weight

for easier handling and

reduced shipping costs

Received 2024

ISE Network Innovators Award

Received 2024 ISE Network Innovators Award

Up to 21% reduction in diameter for installation in smaller ducts and congested manholes

Up to 21% reduction in diameter for installation in smaller ducts and congested manholes

288 fibers housed

within 14mm diameter

double the conventional capacity

288 fibers housed within 14mm diameter double the conventional capacity

Achieved a 50% reduction

in bend diameter, supporting the use of smaller, cheaper handholes

Overview

HFCL's 144-1728F Compact Armored Central Core Intermittently Bonded Ribbon (IBR) Outdoor Optical Fiber Cable family represents a significant advancement in optical fiber cable technology. The use of IBR supports efficient mass fusion splicing and easy routing in closures, significantly reducing termination time. This technology also allows for the production of high-fiber-count cables with reduced diameters, making them well-suited for ever-expanding modern network infrastructure needs. This innovative design family has been recognized with a Silver Award at the 2024 ISE Network Innovators' Awards, highlighting its impact and value in the industry

Applications of HFCL’s 144-1728F Compact Armored Central Core IBR Outdoor OFC

- Engineered for diverse applications, including Data Center Interconnections, Metro Rings, Access Networks, and FTTx Networks

- Ideal for operators deploying fiber optic networks in urban and rural areas, effectively addressing space constraints and environmental challenges

- Specifically designed for applications where durability and protection are crucial, especially direct buried and lashed aerial installations

Challenges Faced

Network operators and installers face multiple challenges with traditional armored optical fiber cables, including:

Large Cable Diameter

The primary challenge was to upgrade the existing Dca-rated cables to achieve the higher Cca-s1a,d0,a1 classification, ensuring enhanced fire resistance and smoke control.

Time-consuming Fiber Access

Removing the multiple protective layers in conventional cables is often time-consuming, resulting in longer installation times and higher labor costs.

Material and System Cost

The need for multiple protective layers in traditional designs increases material consumption and may require the use of larger, more expensive installation hardware

HFCL's Approach

To overcome these challenges, HFCL has developed the 144-1728F Compact Armored Central Core IBR Outdoor OFC with the following innovations:

-

1

Elimination of Inner Tube or Jacket

This cable family removes the need for an inner tube or jacket, reducing overall cable diameter and weight while maintaining required protection and durability

-

2

Hybrid Protective Sheath

A combination of fiberglass rods and corrugated steel armouring provides the necessary toughness for these cables. This allows for smaller cable bend radii, facilitating easier installation in confined spaces. The use of fiberglass rods instead of steel wire enhances safety, eliminating the risk of cuts and punctures from handling cut ends of wire.

-

3

IBR Ribbon Technology

This technology allows for increased fiber packing density and reduced cable size while still supporting efficient mass fusion splicing

-

4

Streamlined Installation Process

By providing direct access to the ribbons once the outer jacket and armoring are removed, the cable design reduces preparation time for splicing, leading to faster deployment.

Success Metrics

The effectiveness of HFCL's innovative cable design is evident in several key metrics:

Direct Access to Ribbons

Simplifies installation by providing immediate ribbon access once the outer jacket and armoring are removed. Achieves 11% time savings on end-entry access and 36% on mid-span accessing compared to dual-jacketed designs.

Industry Recognition

The cable family’s innovative design and performance were recognized with a Silver Award at the 2024 ISE Network Innovators' Awards, underscoring its impact and value in the telecommunications industry.

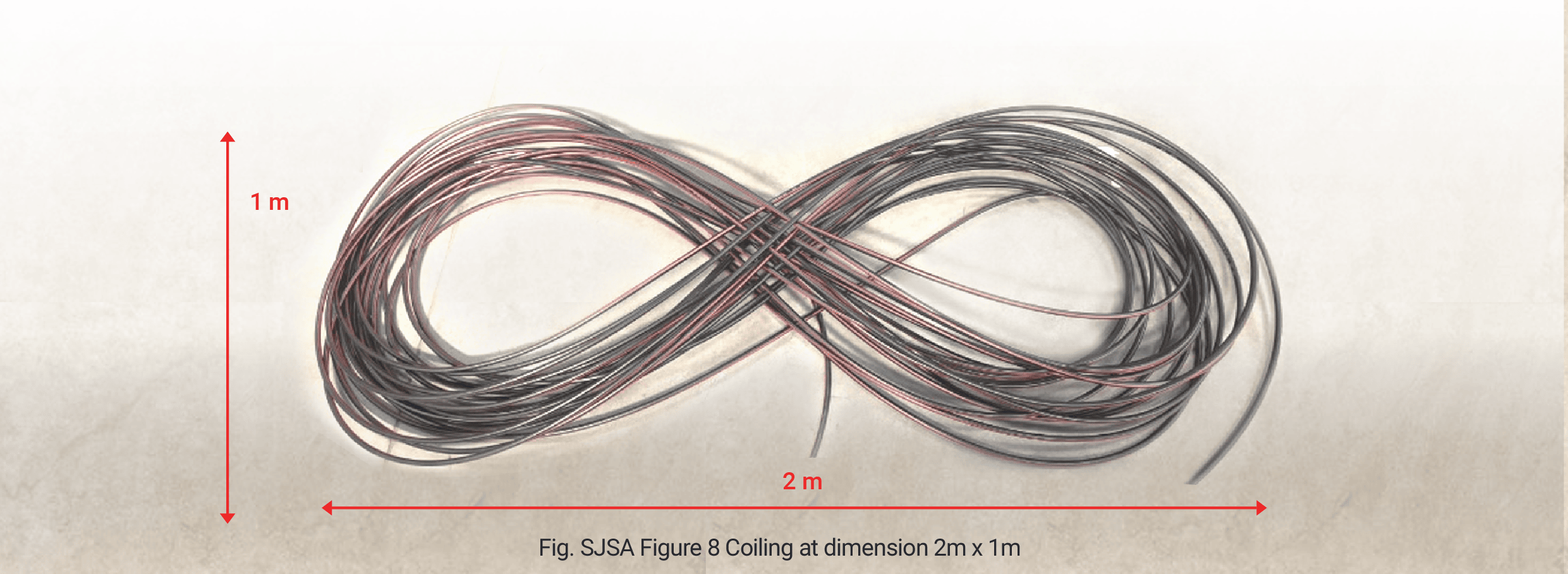

Streamlined Installation

The cable family’s reduced size and high flexibility facilitate easier handling during deployment, whether coiling in Figure 8 or storing slack loops in underground enclosures or on poles. The 288-fiber version fits into a 50% smaller footprint than comparable dual-jacketed designs.

Adherence to Rigorous Quality Standards

Our cable family meets the GR-20 and ANSI/ICEA S-87-640-2016 standards, ensuring consistent quality and reliability across our offerings. This compliance reflects our commitment to industry-leading performance and customer satisfaction.

Cost Reduction

Lower Material Consumption

The elimination of the inner tube or jacket results in up to 43% reduction in cable weight and up to 21% reduction in diameter, directly translating to reduced material consumption. This reduction is also a significant step towards reducing the carbon footprint, aligning with sustainable manufacturing practices

Fig. Low coil diameter – Bend Diameter < 10 x Cable outer diameter

Reduced System Cost

The cable family’s reduced size and improved flexibility allow for the use of smaller vaults and pedestals in underground deployments, thanks to its reduced coil diameters. For example, the 288-fiber design achieves a 23% reduction in coil diameter compared to dual-jacketed armored designs and a 38% reduction relative to central tube designs with flat ribbon, enabling more efficient use of space and lower hardware cost.

Reduced Transportation Cost

The smaller diameter of our cables allows for more cable length per drum, increasing the length of cable that can be shipped in one container or truckload. This efficiency not only lowers transportation cost but also contributes to a smaller carbon footprint by optimizing logistics and reducing the number of shipments required.

Revenue Generation

Rapid Network Expansion

The efficient cable design supports quicker network rollouts, enabling clients to capitalize on new market opportunities and meet the rising demand for high-speed connectivity.

Enhanced Service Offerings

The cost-effectiveness and speed of deployment free up resources, allowing clients to focus on introducing new services and innovations, thereby generating additional revenue streams.

Future-proof Infrastructure

The increased fiber density and reduced footprint of these cables allow the installation of extra fiber in the same space, ensuring that networks are equipped to handle future expansion and technological advancements

Innovative IP-Protected Design

Our latest cable technology is safeguarded by pending Intellectual Property (IP) rights, ensuring market exclusivity. This protection secures our competitive edge and guarantees a reliable, high-performance product for our customers.

Conclusion

HFCL’s 144-1728F Compact Armored Central Core IBR Outdoor OFC family is more than just a set of cables—they are strategic assets designed to meet the challenges of modern telecommunications networks. With its innovative design, efficiency gains, and cost-effectiveness, this product family sets a new standard in optical fiber cable technology, providing long-term value and competitive advantage to network operators, internet service providers, data centers, and telecommunications companies.

HFCL is a leading technology company specializing in creating digital networks for telcos, enterprises, and governments. Over the years, HFCL has emerged as a trusted partner offering sustainable high-tech solutions with a commitment to providing the latest technology products to its customers. Our strong R&D expertise coupled with our global system integration services and decades of experience in fiber optics enable us to deliver innovative digital network solutions required for the most advanced networks.

The company’s in-house R&D Centres located at Gurgaon and Bengaluru along with invested R&D houses and other R&D collaborators at different locations in India and abroad, innovate a futuristic range of technology products and solutions. HFCL has developed capabilities to provide premium quality Optical Fiber and Optical Fiber Cables, state-of-the-art telecom products including 5G Radio Access Network (RAN) products, 5G Transport Products, Wi-Fi Systems (Wi-Fi 6, Wi-Fi 7), Unlicensed Band Radios, Switches, Routers and Software Defined Radios.

The company has state-of-the-art Optical Fiber and Optical Fiber Cable manufacturing plants in Hyderabad, an Optical Fiber Cable manufacturing plant in Goa, and its subsidiary HTL Limited in Chennai.

We are a partner of choice for our customers across India, Europe, Asia Pacific, the Middle East, Africa, and the USA. Our commitment to quality and environmental sustainability inspires us to innovate solutions for the ever-evolving customer needs.