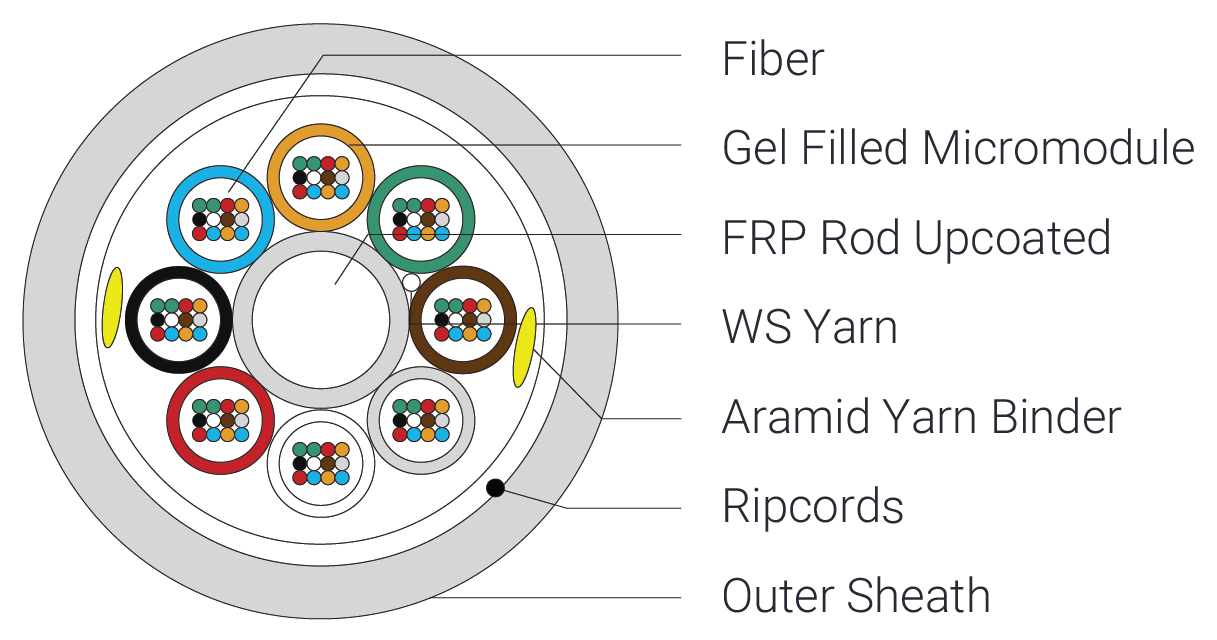

| This cable is available in three major variants with 12F per module construction | ||

|---|---|---|

| Fiber Count | Nominal Cable Diameter | Minimum Inner Diameter of Microduct |

| 12-72F | 5.3mm | 8mm |

| 12-72F | 5.3mm | 8mm |

| 12-72F | 5.3mm | 8mm |

From Space Constraints to

Seamless Installs

How HFCL Solved Fiber Density Challenges

Case Study

Highlights

Tool-free fiber access speeding up installation and maintenance

Micro module

unit kink diameter matches fiber kink diameter with unrestricted buffer skin

Faster installations with low-friction jacket and

air-blown techniques

1.35mm diameter micromodules

with a minimal bend radius, preventing kinks

Fully compatible with micro ducts ranging from

duct

inner diameter 8mm for respective fiber counts

Overview

The customer, an established service provider in Europe, was facing an increasing need for high-density fiber installations due to rapidly growing subscriber demand. Their existing network infrastructure was built using micro ducts with inner diameters of 8mm to 12mm, leaving limited space for further expansion. To address the rising demand for bandwidth, they needed a solution that could offer a higher fiber count while still fitting within the existing duct and networking components like compact closures. HFCL’s innovative Micromodule Micro-cable provided the ideal solution, combining high-density fiber technology with flexible micromodules. This new design enables seamless deployment, easy access for branching, and long-term reliability.

Challenges Faced

The customer faced several specific challenges that needed to be addressed to meet their growing infrastructure requirements:

Microduct Installation

The requested cables had to be compatible with blowing installation methods and fit into micro ducts of sizes 12/8mm, 14/10mm, and 16/12mm, ensuring efficient deployment within the existing microduct network.

Accessible Buffer Tubes

The cable requires buffer tubes for easy midspan access while ensuring a compact fit within closures and vaults without sacrificing accessibility.

Tone-ability for Easy Identification

With multiple cables already installed in the same conduits, the customer required a cable that included a toneable element, allowing for quick and easy identification during maintenance or network upgrades.

Infrastructure Limitations

Existing network constraints restricted the addition of new equipment or cabling without requiring extensive modifications.

High Installation Costs

The need for rapid deployment conflicted with the costs associated with retrofitting existing infrastructure, straining the project budget.

Scaling Fiber Capacity

The expanding subscriber base increased pressure on the service provider to manage increasing fiber count demands without compromising service quality. Scaling Fiber Capacity

HFCL's Approach

To address the specific challenges faced by the customer, HFCL implemented a structured approach that combined microcable technology with advanced micromodule designs.

-

1

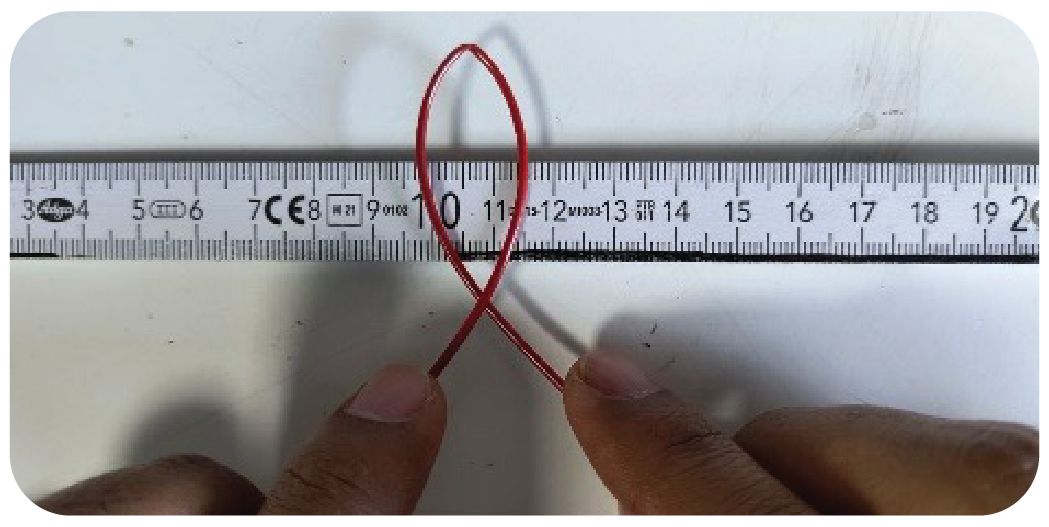

Low Bend Diameter for Easy Routing

The micromodule units feature an exceptionally small bend diameter comparable to the bend radius of the fiber itself. This allows the cable to be routed through limited spaces and closures with no restriction imposed by the tube material, ensuring smooth installation even in constrained environments.

-

2

Blowing Installation for Micro ducts

HFCL’s micro cables were designed specifically for installation using air-blown techniques into micro ducts having inner diameter > 8mm. This method allowed for smooth cable installation into existing ducts without requiring any major changes to the infrastructure.

-

3

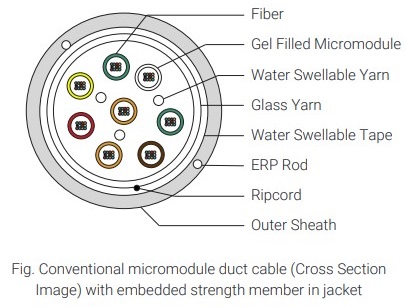

Limitations of Conventional Micromodule Cable

Conventional micromodule cables are designed for larger ducts, such as 50/40mm or 40/33mm, making them unsuitable for the customer’s smaller micro ducts.

-

4

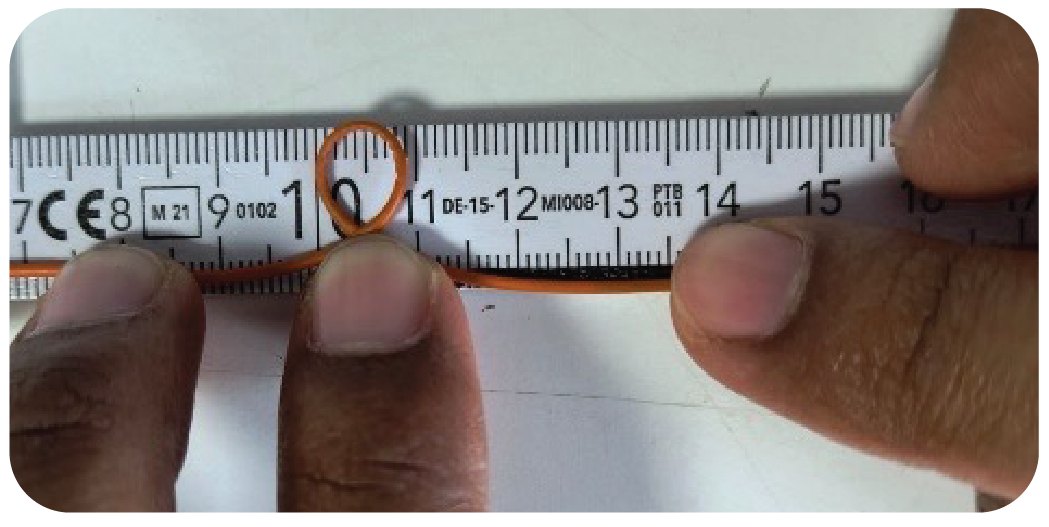

Flexible, Kink Resistant Micromodules

HFCL replaced rigid PBT tubes with flexible micromodule units. These have a kink diameter close to that of the fiber, designed for added bendability and kink resistance. The micromodules allow seamless routing through tight spaces, like closures and vaults, while protecting fiber integrity during installation. Inside closures, micromodules require 5X less space than conventional PBT buffer tubes.

-

Fig. Micromodule low kink diameter

Fig. Kink measurement with conventional tube

-

5

Toneable Cable Design

A key feature of HFCL’s solution was the incorporation of a toneable element. By adding an insulated copper wire along the outer jacket, the cable could be easily identified among other cables, addressing the customer’s requirement for quick identification in crowded ducts.

-

6

High Fiber Density in a Reduced Cable Diameter

HFCL’s micromodule cables were engineered to support higher fiber counts, with each micromodule housing 12 or 24 fibers. The design leveraged bend-insensitive fibers, ensuring that the cable could accommodate a large number of fibers within a lower outer diameter.

-

7

Low-Friction Jacket for Enhanced Blowing Performance

The micromodule cable’s outer jacket is made from low-friction materials, increasing the blowing length by 15-25%. This reduces resistance, allowing longer installations with minimal disruption. The micromodules also underwent rigorous durability testing

-

8

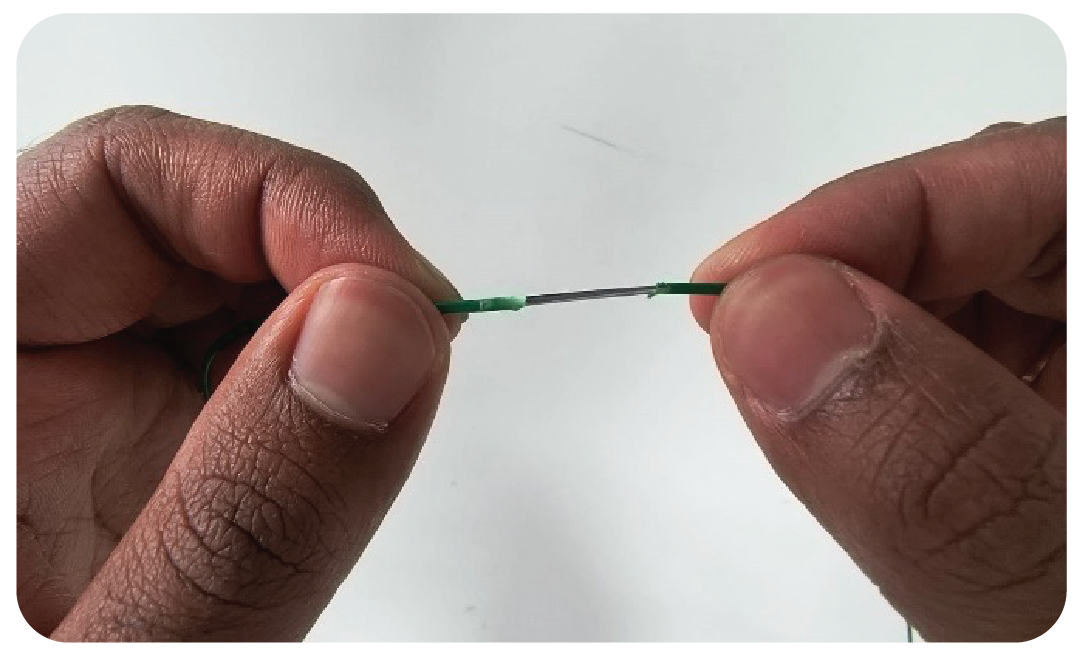

Easy Access Micromodules:

HFCL developed micromodules with a jacket that can be easily peeled by hand, eliminating the need for specialized tools. This innovation simplifies fiber access, making installation and midspan branching easier for technicians.

-

9

Uniform Bending with Central Strength Member

We incorporated the design with a central strength member, ensuring the cable maintained uniform bending properties. This avoided issues related to preferential bending, allowing the cable to be easily installed in smaller-diameter micro ducts.

Key Performance Benefits

Efficient Installation and Longer Blowing Distances

The cables were equipped with a low-friction jacket optimized for air-blown installations, allowing for smoother deployment over longer distances through micro ducts. This design maximized fiber capacity within limited duct space while minimizing installation time and effort. HFCL’s flexible micromodule units further enhanced handling and routing, even in tight spaces like closures and vaults, ensuring faster and more efficient installations while reducing labor and costs, making them ideal for high-density cable deployments.

Minimal Bend Radius

HFCL's micromodules boast an exceptionally small minimum bend radius, with a nominal outer diameter of just 1.35mm for a 12-fiber configuration. This low bend diameter reduces the risk of kinking or fiber breaks, making the cables ideal for deployment in tight, restricted spaces where traditional cables might fail. The bend radius is so small that it matches the bend diameter of the fiber itself. This design allowed the cables to be routed in tight spaces without the risk of kinking or fiber damage, ensuring long-term reliability.

Non-Preferential Bending for Small Microducts

HFCL’s micromodule cables are designed with a central strength member that ensures the cables do not experience preferential bending, which is common in traditional micromodule duct cables designed for larger ducts.

Toneable for Easy Identification

HFCL addressed the customer’s need for easy cable identification by incorporating a toneable element. An insulated copper wire was extruded with the cable’s outer jacket, enabling quick and accurate identification of the correct cable in crowded ducts during maintenance or upgrades, reducing the time and complexity of network operations.

High Fiber Density in Smaller Ducts

HFCL’s micromodule micro-cables provide up to 288 fibers in a single, compact design that allows easy, tool-free access, optimized for micro ducts as narrow as 8mm in diameter. This allowed the customer to increase their network capacity without needing to install larger ducts or make significant changes to their existing infrastructure. The use of bend-insensitive fibers further ensured the cable’s ability to handle high-density fiber counts without compromising performance or installation efficiency.

Low Maintenance and Cost Savings

The lightweight and flexible design of the micromodule cables not only reduced installation effort but also minimized ongoing maintenance costs. The cables’ durability and ease of fiber access allowed for simpler and faster repairs, leading to significant long-term savings for the customer. Additionally, the smaller cable diameter reduced space-related expenses, allowing for more cost-effective deployment and expansion of the network.

Optimized Design for FTTx Networks

Additionally, a key advantage of the micromodule micro-cable design is its ability to withstand reduced pushing and crush forces during installation. This minimizes strain and deformation on the cable’s internal components, allowing for less mechanical protection. As a result, smaller and lighter cables have been developed, making them ideal for FTTx networks. These lightweight designs can be easily installed into microducts, achieving longer installation distances in shorter times with less effort, perfectly suited to meet the rapidly growing demands of FTTx deployments

Gold Awards Honoree

HFCL’s micromodule micro-cables were widely recognized for their innovation and performance, earning the Gold Award in the cable category at the prestigious Merit Awards. This accolade highlighted HFCL’s commitment to developing industry-leading fiber optic solutions that push the boundaries of performance, reliability, and ease of use.

-

Fig. 96F Micromodule Microcable in 6.3mm +/- 0.2mm -

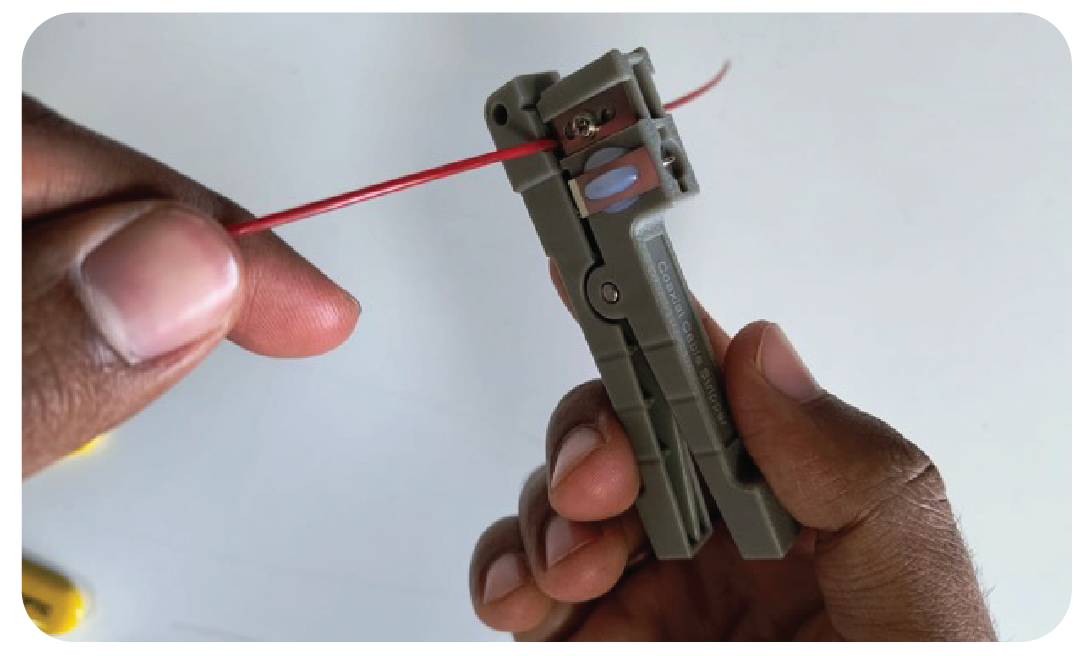

Fig. Micro-loose tube requires a specific tool

Fig. Micromodule sheath removal with no tool

-

This cable is available in three major variants with 12F per module construction Fiber Count Nominal Cable Diameter Minimum Inner Diameter of Microduct 12-72F 5.3mm 8mm 12-72F 5.3mm 8mm 12-72F 5.3mm 8mm

Conclusion

HFCL delivered a range of micromodule micro-cables, ranging from 12 fibers (5.3mm outer diameter) up to 288 fibers (10.2mm outer diameter), with various configurations to suit different microduct sizes. The cables were installed using air-blown jetting, enabling quick deployment over long distances without complex pulling or pushing methods. Notably, a customer from the US was impressed with this design, leading to significant production orders.

In addition, the toneable variant of the cable simplified cable identification, significantly reducing the customer’s operational complexity during maintenance and repairs. Smaller cable diameters and reduced friction allowed installation in 8mm microducts, maximizing existing infrastructure use and minimizing service disruptions.

HFCL is a leading technology company specializing in creating digital networks for telcos, enterprises, and governments. Over the years, HFCL has emerged as a trusted partner offering sustainable high-tech solutions with a commitment to providing the latest technology products to its customers. Our strong R&D expertise coupled with our global system integration services and decades of experience in fiber optics enable us to deliver innovative digital network solutions required for the most advanced networks.

The company’s in-house R&D Centres located at Gurgaon and Bengaluru along with invested R&D houses and other R&D collaborators at different locations in India and abroad, innovate a futuristic range of technology products and solutions. HFCL has developed capabilities to provide premium quality Optical Fiber and Optical Fiber Cables, state-of-the-art telecom products including 5G Radio Access Network (RAN) products, 5G Transport Products, Wi-Fi Systems (Wi-Fi 6, Wi-Fi 7), Unlicensed Band Radios, Switches, Routers and Software Defined Radios.

The company has state-of-the-art Optical Fiber and Optical Fiber Cable manufacturing plants in Hyderabad, an Optical Fiber Cable manufacturing plant in Goa, and its subsidiary HTL Limited in Chennai.

We are a partner of choice for our customers across India, Europe, Asia Pacific, the Middle East, Africa, and the USA. Our commitment to quality and environmental sustainability inspires us to innovate solutions for the ever-evolving customer needs.