Delivering 2x Network Performance

U.S. Hyperscale Tech Giant Transforms Expansion with HFCL’s Compact IBR Cable

Case Study

Highlights

8.8 fibers/mm² density for space-constrained networks

Blown up to

1,500m at 80% duct fill46% lower carbon footprint

than traditional cables

24% smaller diameter

fits in 18/14 & 16/13 microducts efficiently and reliably

Mass fusion splicing

for rapid installation and significant time savings

Overview

To support scalable next-generation broadband services, a leading U.S. hyperscale tech giant needed to upgrade its long-haul network infrastructure. A large-scale fiber deployment initiative in the U.S. sought to double network capacity without expanding its already full 18/14 and 16/13 microducts. The challenge came with tight constraints: IBR ribbon-only design, long-distance blowing, and mass fusion splicing support. To meet these demands, HFCL introduced its 864F IBR Micro Cable (11.2mm), a purpose-built, ultra-compact solution that unlocked higher capacity in limited space, enabling a faster, greener, and infrastructure-free upgrade path.

Customer’s Overview

A major tech giant is fueling the AI revolution with a staggering $65 billion datacenter expansion in 2025, deploying optical fiber overlays and hyperscale campuses across North America.

This cutting-edge investment includes advanced fiber optic networks to support future AI workloads and ultra-low latency for next-gen internet applications, ensuring unmatched global scalability and transformative digital infrastructure leadership.

Challenges Faced

High Fiber Count in Limited Space

Installing 864 fibers in narrow ducts demanded an exceptionally compact cable design without sacrificing durability.

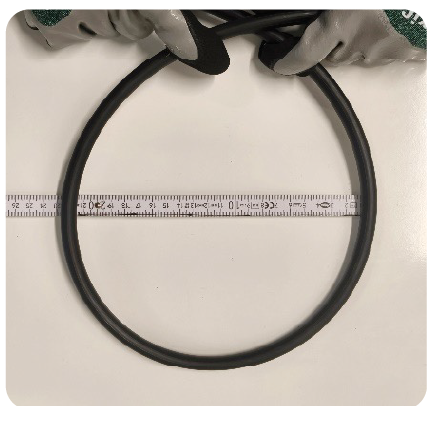

Cable Flexibility & Bend Radius

High fiber count often results in stiffer cables. The cable had to be flexible enough to pass through duct bends.

Minimized Weight for Long Blowing Distances

Heavier cables reduce jetting range. Reducing weight was key to achieving efficient blowing over 1,000+ meters.

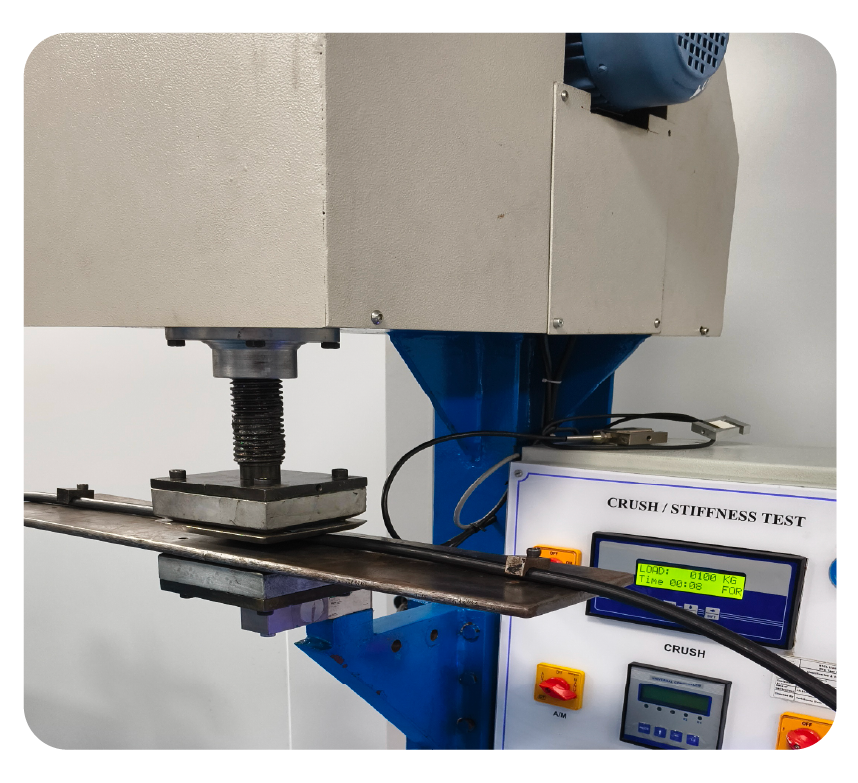

Mechanical Strength & Reliability

The cable needs to withstand handling stress, radial pressure during installation, and remain structurally sound throughout its operational life.

HFCL’s Approach to These Challenges

-

1

Reduced Fiber Diameter for Compactness

HFCL reduced the fiber diameter from 250μm to 200μm, enabling a 24% reduction in the overall cable diameter. This compact design allowed 864 fibers to fit comfortably within existing micro ducts, optimizing space without compromising optical performance crucial where duct expansion isn't feasible.

-

2

Flexible Strength Members for Bend Navigation

Traditional FRP strength members made the cable too stiff, causing blockages during blowing. HFCL introduced less rigid ARP strength members that improved flexibility, enabling the cable to navigate tight bends smoothly while maintaining a safe bend radius.

-

3

Tubeless Design with Binder Yarns

By eliminating buffer tubes and using binder yarns to hold the fiber ribbons, the cable became significantly lighter and slimmer. This streamlined structure enhanced blowing distance and simplified the internal construction for easier handling and installation.

-

4

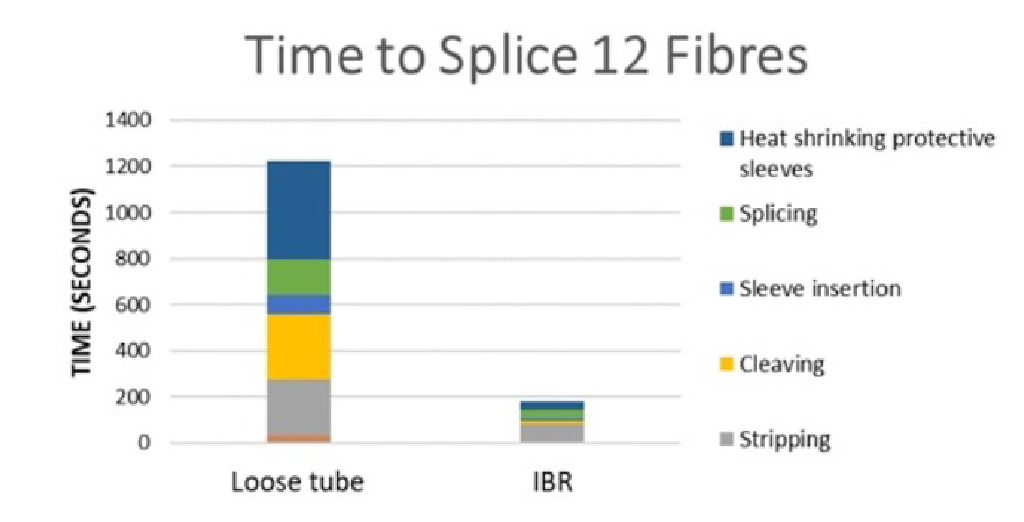

Bonded Ribbon for Fusion and Flexibility

The use of bonded ribbon construction enabled mass fusion splicing as per customer requirements and save ~ 83% of the time as compared to the time required to splice 12 loose fibers.

-

5

Improved Mechanical Durability

Initial trials showed deformation under radial pressure during blowing. The cable construction was optimized with enhance compressive strength up to 1000N without any significant change in fiber attenuation. The result: a more robust cable that maintains structural integrity during installation and throughout its lifecycle.

-

6

Luffa-Shaped Sheath for Blowing Efficiency

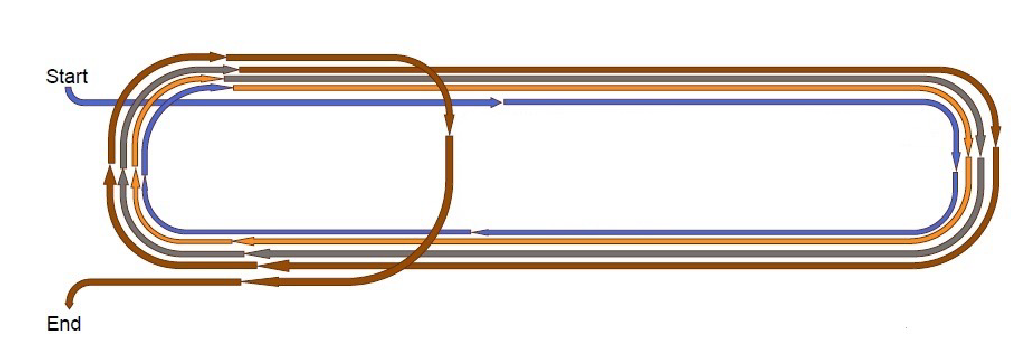

To reduce friction and improve air drag, we adopted a Luffa-shaped outer sheath. This reduced contact with duct walls and increased blowing speed, delivering a 12.5% reduction in installation time over conventional cable designs.

Success Metrics

Key success metrics from the upgrade include:

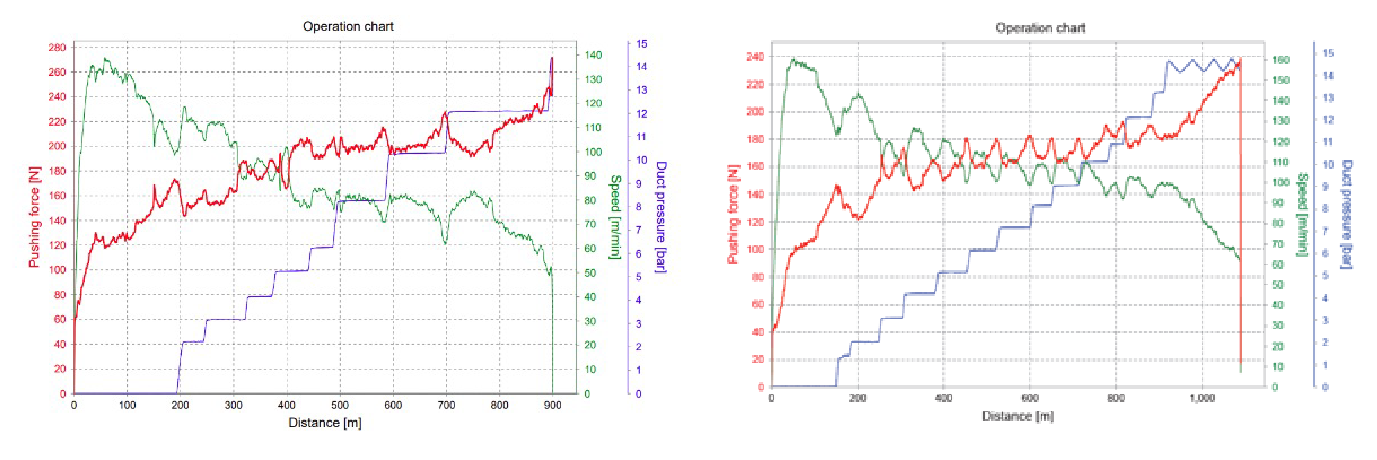

Proven Blowing Performance:

Successfully blown over 1,140 meters through microducts in field testing, meeting performance requirements

Simplified Splicing & Access

Binder yarn construction provides direct access to fiber ribbons after sheath removal, making splicing and field handling faster and easier.

Compact, Sustainable Design

24% smaller diameter, 47.5% less HDPE usage, and 46% lower carbon emissions, reducing material, shipping, and ducting costs.

Standards Compliant

Fully conforms to GR-20, IEC 60794-5-10, and ICEA S-122-744, ensuring high reliability and long-term operational performance.

Applications

The HFCL 864F IBR Micro Cable is ideal for:

Long-Haul Telecom Networks

Lays dense backbones across cities and states

Data Center Interconnections

High-speed, high-capacity interconnects between server hubs

Metro & Regional Fiber Rings

Enables urban and suburban network densification

Enterprise Campus Fiber

Scalable fiber deployments across corporate sites

Conclusion

HFCL’s 864F IBR Micro Cable increased the network capacity by 2x without new infrastructure. Its compact, efficient design solved space and installation challenges while supporting sustainability goals. The deployment sets a benchmark for high-performance fiber in constrained environments.

HFCL is a leading technology company specializing in creating digital networks for telcos, enterprises, and governments. Over the years, HFCL has emerged as a trusted partner offering sustainable high-tech solutions with a commitment to providing the latest technology products to its customers. Our strong R&D expertise coupled with our global system integration services and decades of experience in fiber optics enable us to deliver innovative digital network solutions required for the most advanced networks.

The company’s in-house R&D Centres located at Gurgaon and Bengaluru along with invested R&D houses and other R&D collaborators at different locations in India and abroad, innovate a futuristic range of technology products and solutions. HFCL has developed capabilities to provide premium quality Optical Fiber and Optical Fiber Cables, state-of-the-art telecom products including 5G Radio Access Network (RAN) products, 5G Transport Products, Wi-Fi Systems (Wi-Fi 6, Wi-Fi 7), Unlicensed Band Radios, Switches, Routers and Software Defined Radios.

The company has state-of-the-art Optical Fiber and Optical Fiber Cable manufacturing plants in Hyderabad, an Optical Fiber Cable manufacturing plant in Goa, and its subsidiary HTL Limited in Chennai.

We are a partner of choice for our customers across India, Europe, Asia Pacific, the Middle East, Africa, and the USA. Our commitment to quality and environmental sustainability inspires us to innovate solutions for the ever-evolving customer needs.