Hidden beneath the ground lies an extensive network of underground cables that stretch for millions of miles. This intricate web of infrastructure forms the backbone of the digital age, enabling essential services like water supply, energy distribution, electricity, cable television, internet connectivity, and phone communication. This vast underground network – a complex system of pipelines, underground cables, and wires- is discreetly working just below the surface to support our everyday activities.

In fact, some estimates suggest that this subterranean web spans an astonishing distance of over 20 million miles. Source- Common Ground Alliance (CGA). This staggering number highlights the extensive network of cables that underpin the country's urban and rural areas, enabling vital services for its population. Underground cable is a type of optical fiber cable that enables lightning-fast data transmission for internet, phone calls, and streaming services.

However, our intention is not merely to define underground fiber optic cables as those laid beneath the ground. Instead, we aim to delve deeper into the comprehensive details you seek. But first, let’s understand the structure of an underground cable:

Structure of an Underground Cable:

An underground optical fiber cable consists of several essential components that work together to enable the transmission of digital data through light signals. Here's an overview of the typical structure of an underground optical fiber cable:

Core:

The core is the central part of the cable where light signals travel. It's made of high-quality glass or plastic fibers that have excellent optical properties. The core's refractive index is higher than the cladding (outer layer), which allows light to be guided through total internal reflection.

Cladding:

Surrounding the core is the cladding, which has a slightly lower refractive index than the core. This difference in refractive indices keeps the light signals within the core by reflecting them into it, minimizing signal loss.

The optical fiber is comprised of both the core and cladding. A primary coating is applied to the cladding, serving the purpose of providing cushioning during instances of micro bending. Importantly, this coating does not impact the optical waveguide properties.

Buffer Coating:

The optical fibers are protected by a buffer coating, which is typically made of tough plastic material. This coating shields the delicate fibers from physical damage, moisture, and other environmental factors.

Strength Members:

To add strength and durability, one or more layers of strength members are used around the buffer coating. These can be made of materials like aramid fibers (e.g., Kevlar) or fiberglass.

Water-Blocking Materials:

In underground applications, it's important to prevent water from seeping into the cable. Water-blocking materials, such as water-absorbent tapes or gels, are often included to keep the cable dry.

Armor or Outer Jacket:

The entire cable is covered by a rugged outer layer, often made of materials like polyethylene (PE). This outer layer provides further protection against moisture, physical stress, and other external influences.

Now let’s understand the installation process of an underground cable.

Installation of an Underground Cable:

With underground fiber optic cable installation costs averaging between $1 to $6 per foot, depending on the fiber count (Source: Atlantech|online), careful preparation becomes paramount. Before delving into the process, several crucial steps demand attention:

Step 1: Preparation and Planning

- Obtain necessary permits for right-of-way.

- Identify existing underground utilities like cables and pipes.

- Investigate soil conditions to determine which cable type and plowing equipment would be needed.

Step 2: Cable Placement

- Identify and secure the inner duct.

- Prepare pull-through manholes and apply lubricant.

- Position pulling equipment within limits.

- Install proper guides at the pull-end manhole.

- Hand-feed cable into the manhole.

Cable Placement Precautions (Infographic Content)

- Avoid exceeding the cable's pulling tension, bending radius, and crush load.

- Don't use detergent or petroleum-based lubricants.

- Never set a cable reel on its flange side.

Step 3: Pulling

- Connect the pulling line to the cable's grip.

- Lubricate the duct for reduced tension.

- Establish communication between feed and pull manholes.

- Begin pulling at a slow speed, gradually increasing.

- Maintain a constant pull rate and avoid stops if possible.

Step 4: Final Cable Handling

- Pull cable over the sheave or block if necessary.

- One should not attempt to inch the cable to its final manhole length as it could potentially cause abrupt surges in the cable's end section.

Step 5: Post-installation Inspection

- Inspect the construction area above ground.

- Ensure restoration, marker installation, and proper completion of any road bores.

- Ensure the site is free from any debris or waste materials.

- Confirm all installation specifications are met.

By following these simple steps, an underground cable can be successfully installed, providing reliable connectivity for various applications. Now, it’s time to know why these cables are significant in the world of network and connectivity solutions.

Advantages of Underground Fiber Optic Cables:

Keep Environmental Factors at Bay

Being buried underground provides excellent protection against harsh weather conditions, temperature fluctuations, and external physical damage.

Reduced Interference and Improved Security

Underground placement minimizes electromagnetic interference and radio frequency noise, resulting in improved signal quality and data transmission reliability.

Tomorrow’s Savings Today

Although the initial installation cost of an underground cable may be higher, the long-term savings from reduced maintenance and fewer outages can outweigh the initial investment.

Aesthetics and Urban Planning

Underground cables contribute to a clutter-free and aesthetically pleasing environment in urban areas. They don't obstruct the skyline or contribute to visual pollution.

Surviving Below: Immune to Severe Conditions

During natural disasters like storms or heavy snowfall, underground cables are less likely to be disrupted, ensuring continuous connectivity and communication.

Minimal Signal Loss

Fiber optic cables are inherently less prone to signal loss over long distances, and being underground further reduces attenuation, enabling efficient data transmission over extended routes.

From Connections to Care: Enhanced Public Safety

Underground installation eliminates the risk of accidental contact with high-voltage power lines, enhancing safety for workers and the general public.

Uninterrupted by Wildlife: Ensuring Uninterrupted Connectivity

Underground fiber optic cables are protected from nesting birds or climbing animals, which is a major concern with overhead installations.

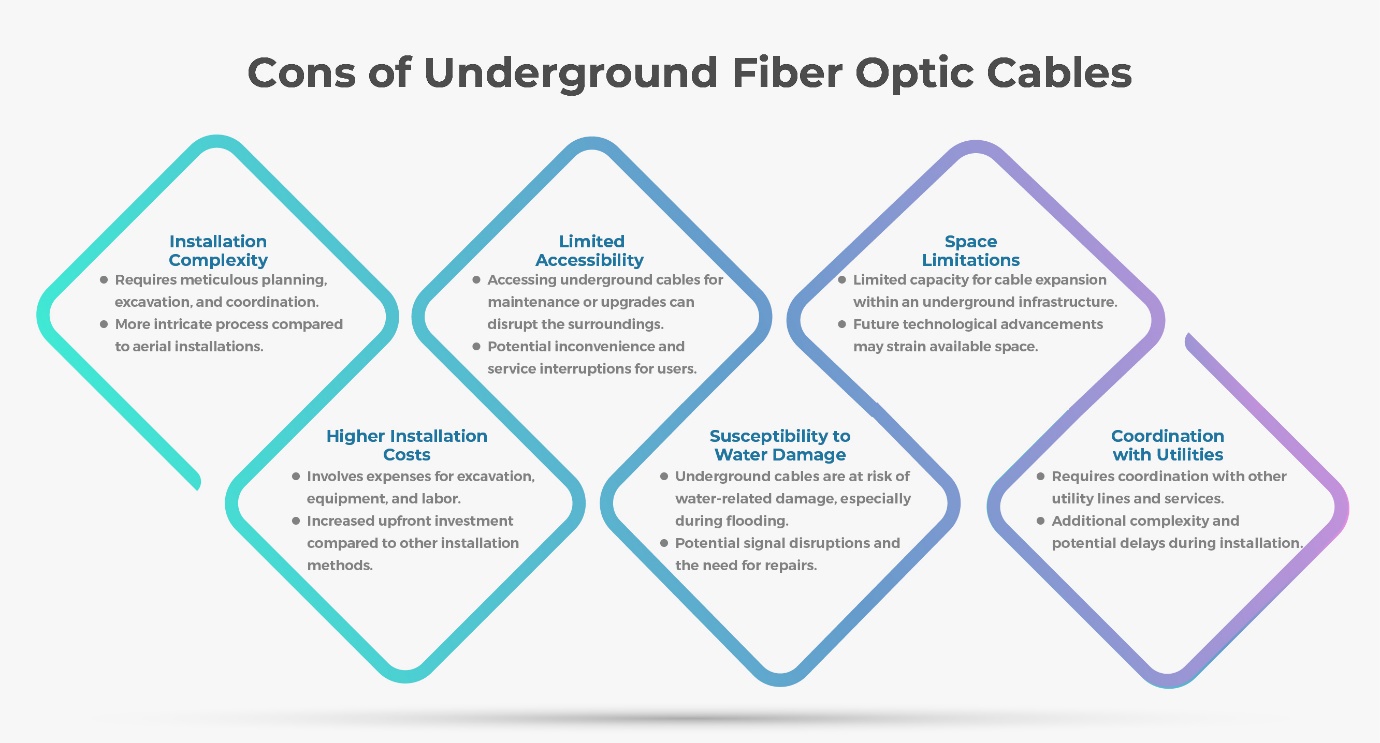

While there are many advantages of an underground cable, there are certainly a few cons of these types of optical fiber cables. The following infographic highlights the disadvantages of these optical fiber cables.

Cons of Underground Fiber Optic Cables:

Final Words:

Underground fiber optic cables are silently powering our modern world. As technology advances, addressing challenges and embracing innovations will ensure that these hidden cables continue to play a vital role in our connected future. So, the next time you browse the internet, connect with your loved ones from different locations or just text your friend a hello, take a moment to appreciate the remarkable impact of underground cables beneath your feet. The silent presence of an underground cable is a cornerstone of our technologically driven civilization.