Whether we're picking a spot for a special celebration or figuring out life-changing stuff like jobs and homes, we engage in planning, compile lists, assess our alternatives, and subsequently take action to achieve success in our chosen endeavors. This process ensures that we make informed decisions, ultimately leading to contentment. The same goes for the tech world, especially when it comes to setting up those optical fiber cables. It's like building the backbone of our internet, and it needs to be done right. In this blog, we explore tips to simplify the process, making optical fiber installation smooth and hassle-free. Just as we weigh our options and compare choices in everyday life, these insights serve as a guide for operators, ensuring a hassle-free and smooth installation that not only meets customer satisfaction but also unlocks numerous benefits for all involved. Join us as we provide valuable tips for simplifying the installation process of optical fiber cables.

Tips for hassle-free Fiber Cable Installation:

Mapping Out

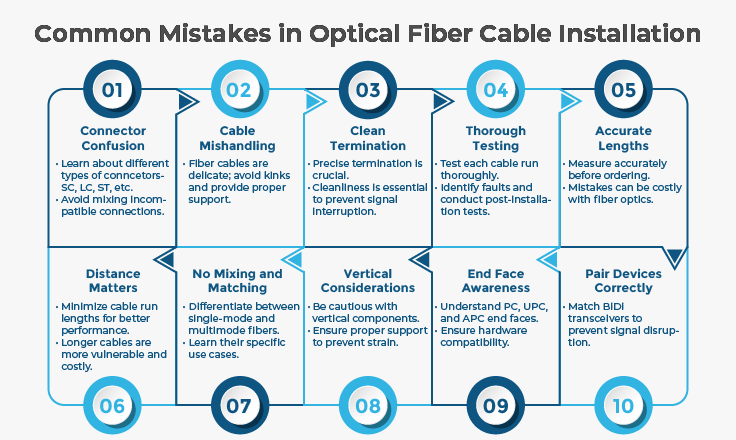

Before diving into the nitty-gritty, let's talk about the first and most crucial tip – planning. It's like mapping out the perfect road trip, where a well-thought-out plan ensures a smooth ride. First of all, identify the cable route, spot potential obstacles, and secure necessary permits. Don't forget the essentials – cable type, connectors, equipment, and a site survey. Ensure ample space for optical fiber cable installation, spot potential hazards, and watch out for underground utilities. A site survey ensures a smooth setup without surprises. There is also a need to ensure that the cable is ready for action post-installation. Planning beforehand will help save time, money, and hassles. In the words of Winston Churchill, "He who fails to plan is planning to fail."

Quality Check is Key

Don't compromise on the quality of your cables. Investing in high-quality materials may seem like a no-brainer, but it's worth emphasizing. The optical fiber cables do not exceed 3-5% of the overall project cost but it’s the backbone that serves the network for 20-25 years. Quality cables ensure a stable and reliable connection in the long run. If you need cables for outdoor fiber installation, opt for cables that have a ruggedized jacket so that they can withstand damage from factors such as UV radiation, water, and chemical exposure. Cables designed for extreme temperatures are your go-to for a reliable connection in both scorching summers and cold winters. In high-humidity zones, choose moisture-resistant cables. In short, choosing the right cable will make all the difference when it comes to a smooth installation. In addition to this, it's crucial to be aware of the cable's diameter, length, and other specifications.

Ensuring Success with the Right Equipment

Now, let's talk tools- without which the optical fiber cable installation is not possible. Poor tools are the recipe for disaster damaged cables, poor performance, and signal loss. Therefore, it is important to invest in top-notch tools – cable cutters, strippers, cleavers – the whole toolkit. Using quality tools ensures precision and excellence. The right choice of tools can help reduce the risk of injury during the optical fiber cable installation. Moreover, different types of cables require different tools or procedures to be installed efficiently. Overall, it is crucial to make the right choice when it comes to tools and equipment for a successful cable installation.

Future-Proof Your Fiber Cable Installation

Technology evolves rapidly, so plan for the future. Install extra fibers and consider scalability to accommodate the ever-growing demand for faster and more robust connections. As Bill Gates once said, "We always overestimate the change that will occur in the next two years and underestimate the change that will occur in the next ten." Apart from that, you need to ensure that your cables are protected against the elements. Proper weatherproofing safeguards your installation from rain, snow, and temperature fluctuations. Furthermore, it is also important to protect the optical fiber cable during the installation process by simply using protective sleeves or conduits to protect the cable from damage and bending or kinking the cable. This is necessary to avoid signal loss or complete failure of the system. And not to forget, before and after, test the cable. Regular checks ensure your cables are in top form.

Use of Proper Splicing Technique

Splicing fiber optic cables is a pivotal step in their installation, and getting it right is non-negotiable. Precision matters here. Using proper splicing techniques, particularly fusion splicing, is the linchpin for ensuring a secure and dependable connection. When splicing isn't done correctly, it can lead to signal loss and weak connections, potentially resulting in system failures. Fusion splicing, regarded as one of the most accurate methods, involves the use of heat to fuse the ends of two fibers, creating a permanent connection. This meticulous process guarantees minimal signal loss and maintains a high-quality splice, ensuring a secure and uninterrupted connection. Employing precise cleaving techniques before splicing further enhances the overall quality of the splice. Equally crucial is having the right equipment—fusion splicers, cleavers—and a well-trained operator to execute a successful splicing process.

Navigating Challenges Below the Surface

Going underground? Buckle up – it's a whole new world with its own set of challenges. It's like a treasure hunt, but the treasures are cables, and the obstacles are buried utilities. Identify buried utilities and choose the right protective covering. This will help avoid obstacles, protect your cables, and help in a successful fiber cable installation.

Right Connectors for the Right Installation

Ensure connectors match cables and equipment. Incompatible connectors are the network's version of a messy breakup – signal loss and chaos. Opt for connectors with low insertion loss and back reflection.

Safety First

Safety is non-negotiable. Installing cables without safety measures is like a tightrope walk without a safety net. Proper grounding and bonding are your safety net that protects you from potential disasters. Follow Occupational Safety and Health Administration (OSHA) regulations to the letter to keep everyone safe during the fiber cable installation process.

The Pro Play: Hiring the Experts

Not a cable installation expert? No worries – call in the pros. Professionals bring knowledge, expertise, and the right tools to the table. In addition to that, take the time to label your cables clearly. This makes future maintenance and troubleshooting a breeze. Labeling your cables is like putting name tags on them – it makes everything easier to manage.

Training Matters

Equip your team with the right knowledge and skills. A well-trained team ensures efficiency and reduces the chances of errors during installation. Keep everyone in the loop. Effective communication among team members and with clients ensures that everyone is on the same page, reducing the chances of misunderstandings. Communication is the glue that holds your installation plan together.

Regular Maintenance Checks

Don't just set it and forget it. Regular maintenance checks ensure that your installation remains in peak condition, preventing potential issues before they escalate. Create a comprehensive documentation of your installation. This serves as a valuable reference for future upgrades, expansions, or any troubleshooting needs.

Final Words

Installing optical fiber cables doesn't have to be daunting. By following these tips, you can ensure a smooth and efficient optical fiber cable installation process. Remember to plan meticulously, handle the cables with care, use proper tools, and test thoroughly. With attention to detail and patience, you'll pave the way for reliable and high-speed communication through optical fiber connections.