In the post-COVID-19 era, there is a greater dependency on digital infrastructure as more and more people rely on telecommunications networks to shop, bank, work remotely, and stay connected to their loved ones. Although worldwide data consumption is projected to grow 300% over the next 5 years, the cost of deploying networks has increased. At the same time, consumer and business connectivity solutions have been commoditized, and heavy competition makes it challenging for service providers to raise their rates. Service providers and network operators are under immense pressure to provide affordable, high-performance connectivity solutions while minimizing deployment and maintenance costs.

Optical fiber is the most effective solution for high-speed backbone and distribution applications, with optimal network economics. Over the last few years, a unique type of optical fiber cable, micro-module cables has become more popular. Micro-module cables are emerging as a solution for network operators to increase capacity at optimal system cost. Service providers in several parts of the world, particularly Western Europe, are leveraging micro-module cables to maximize capacity while bringing down their spending on infrastructure and deployment costs.

What are micro-module cables?

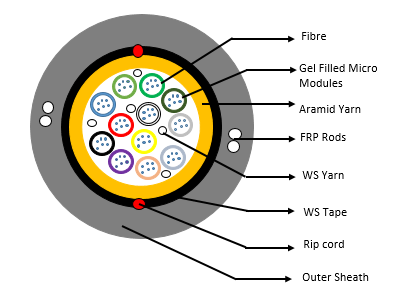

The building block of these cables is individual micro-module units, in which multiple optical fibers are housed inside a thin, flexible, compact polymeric jacket, instead of the thicker, rigid tubes used in traditional loose tube cables. Multiple micro-modules are contained within a protective outer jacket. The small size and flexibility of micro-modules allow the use of compact, high-density fiber management and can reduce operator system costs in many applications, including aerial, underground, and multi-dwelling unit installations.

Traditional Fiber Optic Cables – Bottlenecks:

Conventional loose tube fiber optic cables typically bundle individual fibers within stiff tubes stranded around a central strength member under a jacket. While effective in many applications, these traditional loose tube cables have limitations:

Micro-module cables - A Compact and Flexible Solution

Micro-module cables have emerged as a potential game-changer for network operators looking to increase data transmission capability. Here are the key advantages offered by micro-module fibers:

High fiber density, small footprint

Micro-module cables can pack in a significantly higher number of fibers within a smaller diameter than traditional loose tube cables. This makes them ideal for situations where space is limited, such as data centers, enterprise buildings, and conduit pathways.

Unmatched flexibility for easier and faster installations/space optimization:

Several features of micro-module fiber cables make them perfect for challenging deployments. These cables have smaller diameters than traditional cables, which makes them easier to install in tight spaces, allows the use of smaller conduits and closures, and better utilizes existing infrastructure.

Enhanced bend resistance:

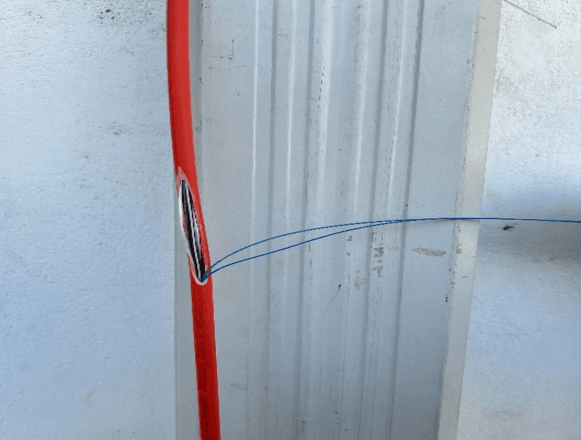

The individual modules provide additional protection to the fibers, making them more resistant to bends and kinks during installation and maintenance.

Mid-span access advantage:

Micro-module designs provided with thin, easy-to-peel jackets offer easy access to individual fibers with no need for additional tools, as the thin skins can be peeled off by fingers. This simplifies future additions, drops, and maintenance work.

Gel-filled modules getting replaced by dry micro-modules

While petroleum-based gels are commonly used to block water ingress into micro-modules, gel-free micro-module constructions have been developed. Dry micro-modules use superabsorbent polymers instead of gel to block water penetration. This results in significant time savings during installation, as the fibers do not need to be cleaned before splicing. The fibers are immediately ready for cleaving and splicing when the micro-module jacket is removed. An added benefit is a cleaner work environment, eliminating sticky gels as well as the use of citrus degreasers for gel removal.

HFCL’s Micro-module Cables- Product Portfolio

HFCL offers a wide variety of micro-module products, including underground direct-buried cables, all-dielectric self-supporting (ADSS) cables, and ultralightweight overhead aerial cables. For duct installation, high fiber count cables are available with fiber counts up to 1728F.

The lightweight and small size of HFCL’s micro-module cables make them easier to transport and store than traditional loose tube cables. These cables are designed for easy termination through tool-free peeling of the micro-modules, reducing overall installation time. The small size, flexibility, and kink-free handling of the micro-module units can support the use of reduced-size hardware, including closures, pedestals, and vaults, reducing the system cost of network expansion.

The cables meet all relevant international standards and have been deployed in several geographies for backbone, distribution, and access applications.

1.Direct burial underground cables - Built for the subsurface

Features: These micro-module cables’ outer sheaths are designed for robustness in direct burial applications, providing resistance against water ingress, crush loads, and impact loads. Resistance to rodent attack can be provided through the use of rodent-repelling jacket additives or corrugated steel armor tape. Taken together, these features ensure long-term protection against harsh underground environments.

Applications: Ideal for underground network expansion, point-to-point connections between buildings, and fiber optic installations in trenches.

2. Duct micro-module cables - Confined space champions

Features: Engineered with a reduced outer diameter compared to standard underground cables, these micro-module cables are perfect for existing conduit systems or situations with limited space availability.

Applications: Excellent for congested underground pathways, installations within existing ducts, and deployments in locations where space is at a premium.

3. ADSS (Aerial Dielectric Self Supporting) micro-module cables - Taking to the skies

Features: These cables are lightweight and possess high tensile strength, enabling them to be self-supporting when suspended between poles or overhead lines, avoiding the need for messenger wires and time-consuming aerial lashing. The outer jacket is UV-resistant and weatherproof, ensuring reliable performance in aerial environments.

Applications: Perfect for overhead fiber optic deployments between buildings, long-distance aerial network connections, and situations where underground installation is not feasible.

4. Ultra-lightweight overhead (ULW OH) cables - The ultra-light solution

Features: These micro-module cables are the epitome of lightweight design, making them ideal for applications where minimizing weight load on existing poles or structures is crucial. They maintain excellent tensile strength despite their weight reduction while supporting ‘work safe’ requirements by breaking when snagged by a vehicle or hit by a falling tree.

Applications: Ideal for medium-span and short-span aerial deployments, installations on existing poles with limited weight capacity, and situations where reducing strain on supporting structures is critical.

5. Air-blown micro-module cables – Optimised efficiency

Features: These cables are specifically designed for air-blown installations within micro ducts. Their smooth, low-friction outer jacket allows for easy and efficient deployment using compressed air within micro ducts. Applications: Perfect for high-density fiber optic deployments in urban areas, installations within pre-existing micro ducts, and situations where minimal disruption to the surrounding environment is desired.

6. Premises distribution cables - Building internal highways

Features: These micro-module cables are designed for indoor applications within buildings. They offer high fiber density for efficient cable routing throughout a building's internal network. These cables incorporate flame-retardant materials to meet relevant fire safety codes and requirements.

Applications: Ideal for enterprise building networks, telecommunications exchanges, and any indoor application requiring high-bandwidth data distribution.

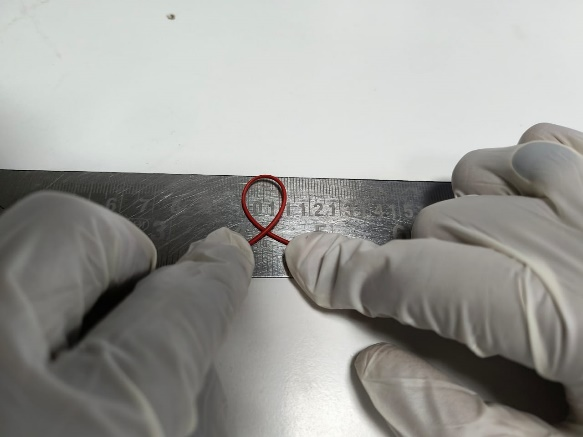

7. Pull back riser cables - Vertical ascents made easy

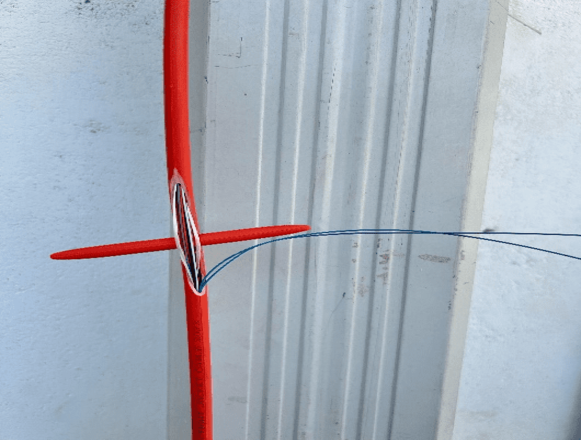

Features: Engineered for vertical installations within buildings or structures, these micro-module riser cables possess flame-retardant properties and meet stringent building codes for vertical riser applications. They are also designed for easy pulling and installation within vertical pathways. As shown in the picture below, individual micro-modules can be readily pulled out of a window and cut into the sheath to drop fibers to an individual floor of a building.

Applications: Perfect for high-rise building network connections, riser shafts within buildings, and any vertical application requiring fire safety compliance.

1728 fiber micro-module cable

HFCL is at the forefront of global innovations and developments in optical fiber cables. Realizing the crucial need of network operators for high-density fiber cables, HFCL has recently developed a 1728 fiber micro-module cable, with a 33% smaller diameter when compared with traditional cable. The smaller form factor reduces material usage and reel size while allowing for easier cable management and installation.

In closing

Deployment of micro-module optical fiber cables can address space constraints, improve installation efficiency, and offer greater flexibility for future network growth. As the demand for bandwidth continues to surge, this innovative technology is poised to play a vital role in building the high-capacity networks of tomorrow.

At HFCL, we are committed to providing sustainable solutions for the future. Our micro-module cables are not just space-savers; they are built for diverse applications, from aerial deployments to underground installations. With exceptional durability and a range of specialized options, they ensure robust performance without compromise.

As we strive towards a greener planet, HFCL's micro-module cable technology paves the way for building high-capacity networks with a lower carbon footprint. Our commitment to sustainability can help ensure easier access to advanced technology while safeguarding our planet for generations to come.