Based on the research conducted by Reports and Data, it is predicted that the global fiber optics market will witness significant growth, with an estimated value of USD 11.18 Billion by the year 2030. Furthermore, the market is expected to grow at a CAGR of 9.3% during the forecast period. This rapid growth is attributed to the increasing adoption of high-speed internet and the demand for advanced communication networks across various industries, including telecommunications, IT, healthcare, and transportation. Amidst this quest for improved connectivity, loose tube microcables have emerged as the go-to solution for industries seeking robust fiber optic cable solutions capable of withstanding demanding environments.

In a world where data permeates every aspect of our lives, from communication to commerce, the reliance on robust connectivity has become paramount. Each passing day pushes us further into the digital realm, with activities ranging from phone calls to online transactions and even purchasing furniture seamlessly facilitated by the backbone of our interconnected world – optical fiber cables. This medium through which data flows, propels us toward a future with reliable connectivity and incredibly fast data transmission speeds. Let’s now delve into the crucial role of loose tube microcables in shaping our interconnected world.

Unveiling Loose Tube Microcables:

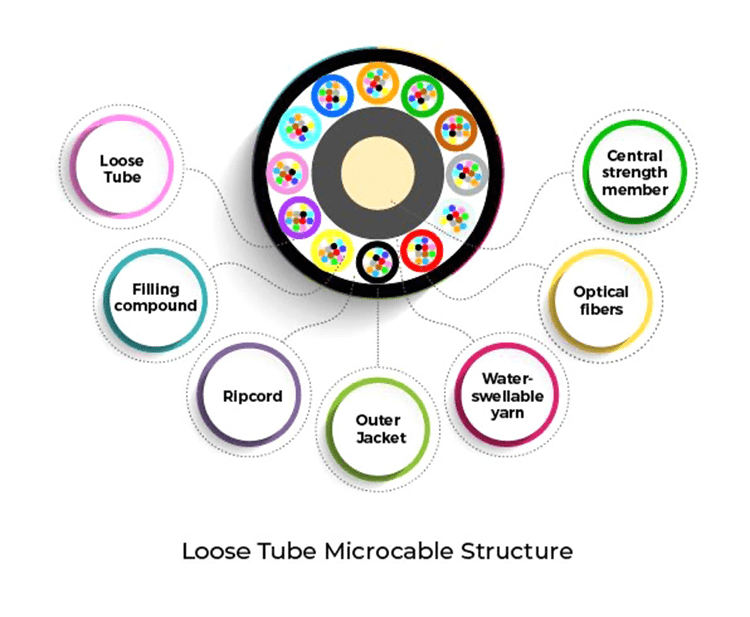

Loose tube microcables are designed to protect optical fibers when deployed in a number of different scenarios. The cable design comprises a central strength member surrounded by tubes of loosely arranged optical fibers, offering excellent resistance against moisture, temperature variations, and physical stress. Let’s understand the design of a loose tube microcable in detail:

Structure of the Loose Tube Microcables:

Loose tube microcables have a simple yet effective structure. Groups of individually coated fibers are organized in a series of plastic tubes within the cable. This plastic tube sub-unit is designed to be robust, protecting the fibers from damage under various mechanical loading. To keep moisture out, the tube is filled with a special gel that blocks water from entering.

The strength of loose tube microcables lies in their ability to accommodate different use cases. primarily deployed within microducts. Their sturdy design allows them to withstand a variety of different installation scenarios and conditions. Experts strongly recommend that the right installation method for loose tube microcables is to blow them into the microducts, although short runs of microcable installed under low tension may also be acceptable.

Benefits of Loose Tube Microcables:

The fiber optic industry is witnessing several exciting trends, shaping the future of loose tube microcables:

Increased Fiber Density:

As data demand surges, there is a growing need to accommodate more fibers within a limited physical space. Manufacturers are continuously innovating to develop loose tube microcables with higher fiber counts, allowing for increased data transmission capacity.

Bend-Insensitive Fibers:

Traditional fiber optic cables are susceptible to signal loss when subjected to excessive bending. However, recent advancements have led to the development of bend-insensitive fibers, which minimize signal degradation, enhancing the overall performance and flexibility of these microcables.

Enhanced Installation Techniques:

Installers are seeking efficient and cost-effective installation methods. Technologies such as air-assisted installation within microducts are gaining popularity, enabling the faster and easier deployment of these fiber optic cables.

The Future of Loose Tube Optic Fiber Cables:

With the ever-increasing demand for faster and more reliable data transmission, the future of optic fiber cables, particularly loose tube microcables, looks incredibly promising. Here are a few key factors that will shape their trajectory:

5G and Beyond:

The deployment of 5G networks and the imminent arrival of 6G will require extensive fiber optic infrastructure. Loose tube microcables, with their small size and ease of installation, will play a crucial role in supporting the exponential growth in data traffic and the proliferation of connected devices.

Internet of Things (IoT):

As IoT devices become more prevalent in various sectors, such as smart cities, healthcare, and industrial automation, the demand for robust and scalable connectivity will skyrocket. These microcables, with their ability to be installed in a variety of scenarios, will provide the backbone for seamless IoT integration.

Data Centers and Cloud Computing:

The rapid expansion of data center infrastructure and our increased reliance on cloud computing technologies demand highly efficient and robust connectivity solutions. These fiber optic microcables offer the deployment scalability required to support rapid growth in data center networks.

Final Words:

Loose tube microcables have ushered in a new era of connectivity, providing unmatched durability, reliability, and performance. As we embark on a data-driven future, loose tube microcables will continue to play a pivotal role in connecting the world and enabling digital transformation across various sectors.

The potential and promise of these fiber optic cables are vast, and their influence on the global connectivity landscape cannot be understated. As we embrace this technology, we are witnessing a revolution in the way we communicate, collaborate, and drive innovation in an increasingly interconnected world.