Fiber optic termination enables efficient connectivity and data transmission between two fiber cables or between cables and network devices. It demands careful and meticulous handling of delicate fiber strands to ensure optimal performance. Fiber has emerged as a medium of choice for high-quality, long-distance data transmission. As Fiber-to-the-Home (FTTH) deployments gain momentum, network operators are under pressure to accelerate optimum coupling cost-effectively. It is critical to opt for the right fiber optic termination strategy, as the wrong approach can not only increase the project cost but also lead to unavoidable delays.

What is Fiber Optic Termination?

Fiber optic termination is the process of connecting fiber optic cables to devices or other cables to ensure reliable and efficient data transmission. This process is essential for ensuring efficient light transmission, minimizing signal loss and maintaining network integrity. It is a crucial component of FTTH deployment where numerous terminations are required to connect individual homes to the main network infrastructure to provide the best possible connectivity.

Proper fiber optic termination is a necessary step in installing a fiber optic network to ensure there is no loss of signal strength over long-distance transmission. Any mistake in the termination process can increase insertion loss, leading to subpar network performance. Without effective termination, signal quality can degrade, leading to poor network performance.

What are the different types of fiber optic termination?

Essentially, there are two ways to terminate fiber optic cables: connectors and splicing. Both approaches come with their advantages and disadvantages. Network operators can opt for the fiber optic termination method based on the deployment timelines, costs and the type of gear being used. Whatever be the method being used for fiber optic termination, it should ensure optimal performance and strength.

Connectors:

Connector termination is the process of attaching a connector to the end of a fiber optic cable, enabling easy disconnection and reconnection of the cable when needed. In essence, a fiber optic connector aligns and joins the cores of different cables or connects a cable to a device, allowing light to pass through efficiently. Choosing the right connector is critical for maintaining high network performance. Various types of connectors are available for connecting fiber optics to devices or network equipment, including Straight Tip (ST), Subscriber Connector (SC), Ferrule Connector (FC), and Lucent Connector (LC).

Network operators can use factory or field-terminated connectors in an FTTH deployment. Essentially, factory-terminated connectors are pre-terminated and provide high performance and improved reliability with minimal optical loss. Since pre-terminated fiber cables come with connectors attached, they reduce the installation time and labor expenses. However, they are more expensive than field-terminated connectors.

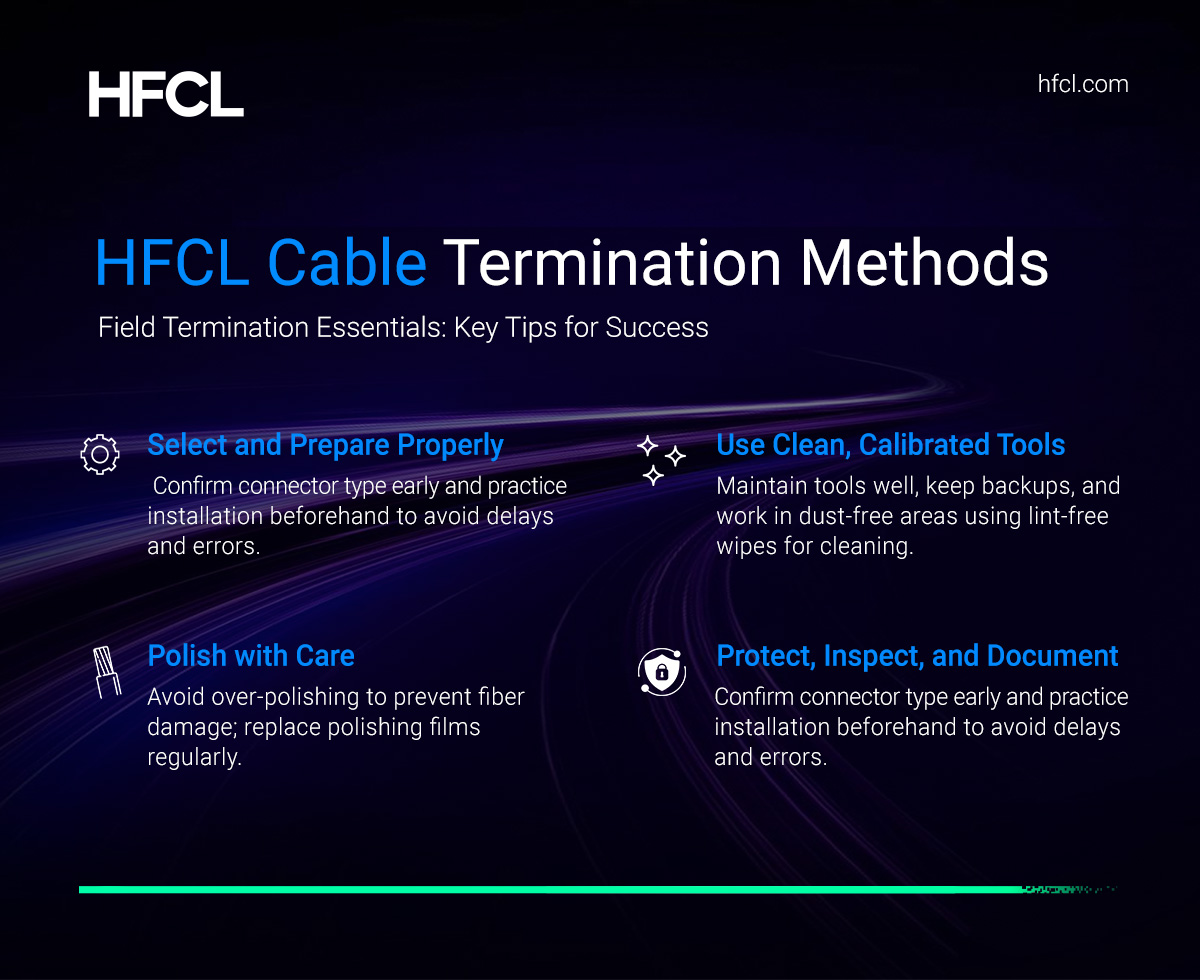

On the other hand, field-terminated connectors provide greater flexibility but require specialized skills. They demand high precision and can be more time-consuming than factory-terminated connectors.

Splicing:

Splicing involves directly joining two fibers without using connectors, aligning them to form a connection. This method provides a permanent bond, usually resulting in lower signal loss than connector termination. Splicing is especially effective for repairing broken cables, though it requires skilled and experienced technicians. There are two main types of fiber optic splicing: mechanical and fusion.

Comparing Mechanical and Fusion Splicing

Mechanical splicing, as the name implies, involves aligning and joining two fibers using fixtures, but without permanently bonding them. The fibers are held together by a mechanical splice device, which uses an index-matching gel to reduce signal loss at the connection point. This splicing method is particularly well-suited for multimode fiber applications.

On the other hand, in fusion splicing, two optical fibers are permanently welded together. This type of splicing requires a fusion splicer, making it more expensive than mechanical splicing. The fusion splicer aligns the two fibers and melts them together using an electric arc. Fusion splicing is typically used in long-haul and outdoor networks and is more appropriate for single-mode fiber networks.

The insertion loss in a mechanical splice is typically greater than in a fusion splice, which is between 0.2 dB and 0.75 dB and less than 0.1 dB. Insertion loss refers to the signal loss that occurs as light travels through a fiber cable. Fusion splices are generally more effective at preventing cable failure and maintaining signal strength, as they result in lower insertion loss compared to mechanical splices. In mechanical splices, the fiber cores are only aligned and not permanently fused, which can lead to higher insertion loss.

Where cost is concerned, fusion splicing is more expensive because it requires investment in the fusion splicer. However, it provides a lower variable cost compared with mechanical splicing. This means that in spite of the higher initial investment, fusion splicing may be more cost-effective in the long run.

Which is better: Connector Termination or Splice Termination?

Both connector termination and splice termination have their own merits and demerits. Factors such as labor and costs should be thoroughly evaluated before deciding in favor of one over the other.

A key advantage of using connectors is that they are more cost-effective, as no investment in a fusion splicer is required. On the other hand, the insertion loss is higher in connector-based termination than in splicing termination. Splicing can also be used to bring together different types of fiber optic cables. It is also known to provide a more reliable connection with significantly lower insertion loss.

| Feature | Connector Termination | Splice Termination |

|---|---|---|

| Process | Attaching a connector to the fiber end. | Joining two fibers directly using mechanical or fusion splicing. |

| Types of Connectors/Splices | SC, LC, ST, FC connectors. | Mechanical splices or fusion splices. |

| Equipment Required | Connector crimping tools, polishing tools, and an inspection microscope. | Mechanical splicing tools or a fusion splicer machine. |

| Skill Level | Moderate; achievable with basic training. | High for fusion splicing; moderate for mechanical splicing. |

| Time Required | Quick; each termination can be completed in a few minutes. | Moderate; mechanical splicing is relatively fast, fusion splicing takes longer. |

| Initial Cost | Low to moderate; varies with the quality of connectors and tools. | Moderate to high; mechanical splicing is cheaper than fusion splicing. |

| Insertion Loss | Higher; typically, 0.2 - 0.5 dB per connector. | Lower; mechanical splicing typically 0.2 - 0.75 dB, fusion splicing 0.02 - 0.05 dB. |

| Durability | Prone to contamination and physical damage, needing regular maintenance. | Mechanical splices are less durable than fusion splices, which are very durable. |

| Reliability | Moderate; can be affected by environmental factors and physical handling. | High for fusion splices; moderate for mechanical splices. |

| Flexibility | High; easy to disconnect and reconnect, ideal for testing and troubleshooting. | Low; designed for permanent connections, not meant for frequent reconfiguration. |

| Maintenance | Requires regular cleaning and inspection to maintain performance. | Minimal for fusion splices; mechanical splices may need occasional inspection. |

| Application Suitability | Suitable for scenarios needing frequent reconfiguration or testing. | Ideal for permanent, high-performance installations. |

| Environmental Impact | Susceptible to dust, dirt, and physical stress. | Fusion splicing is stable under various conditions; mechanical splices less so. |

| Use Case Examples | Patch panels, equipment connections, areas with frequent maintenance needs. | Long-term FTTH deployments, critical network connections, high-performance requirements. |

In closing

Opting for the right fiber optic termination solution for FTTH network deployment can not only ensure cost effectiveness but also provide users with more reliable and superior-quality network services. Both connectors and splicing have their own benefits and drawbacks. Evaluating the factors and project requirements will help in choosing the right fiber optic termination solution.