Think about your favorite pair of headphones. You know how frustrating it is when the connection is loose, and the sound cuts in and out. It’s the same with fiber optic connectors – they are the crucial links that ensure data flows smoothly, without interruption. Just like how a snug headphone jack delivers clear sound, a well-installed fiber optic connector ensures reliable, high-speed communication. If you're diving deep into the world of fiber optic connector installation, you're in the right place. The Cable Connector Market is projected to witness significant growth, with an estimated value of USD 102.81 billion in 2024, expected to surge to USD 146.24 billion by 2029. This growth, at a CAGR of 7.30% during the forecast period (2024-2029), is attributed to escalating demands in media, entertainment, and internet accessibility across emerging economies. (Source- Modor Intelligence Report- Cable Connector Market Size & Share Analysis). With an increasing number of television and internet subscribers, alongside the widespread usage of smartphones, PDAs, and tablets, the necessity for cable connector adapters has skyrocketed, becoming indispensable for establishing effective networking infrastructures.

Why Fiber Optic Connectors Matter?

In the world of telecommunications, fiber optic patch cords are essential for connecting devices to the network. Central to these cords are fiber optic connectors, which are carefully designed ceramic components that ensure precise connections between fibers.

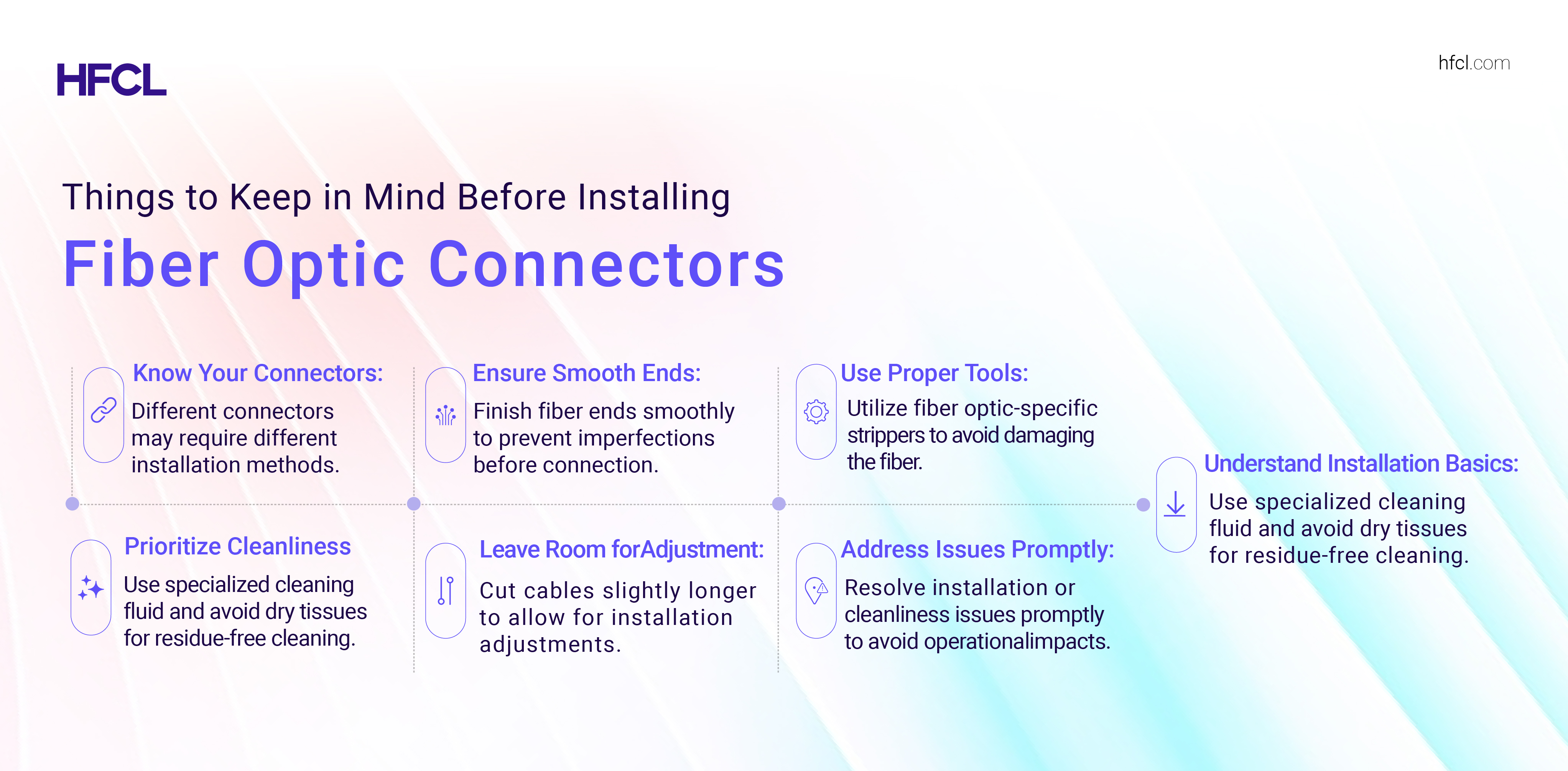

Installing these connectors onto optical fibers is a precise process that requires attention to detail. The method varies depending on the type of connector used. Whether it's a simple no-epoxy/no-polish connector or a more complex epoxy-and-polish connector, each requires its own approach.

Preparation: The Foundation of Success

Before you even touch the fiber, setting up your workspace is key. Think of it like cooking in a clean kitchen – fewer mistakes and better results.

-

Clean Work Environment:

Understand that while you are preparing for a fiber optic connector installation, dust is your enemy. Even a tiny particle can disrupt data transmission. Set up in a clean, controlled environment. -

Proper Tools:

Invest in quality tools. You’ll need fiber strippers, cleavers, microscopes, and cleaning materials. A good toolset might cost more upfront, but it’s worth it in the long run. -

Understand the Connector Type:

There are different types of fiber optic connectors like SC, LC, and ST, each with its installation nuances. Familiarize yourself with the specifics of the one you’re working with.

Cable Preparation: Getting the Basics Right

Traditional ribbon cables are effective but can be rigid during routing, while loose tube designs, though flexible, slow down deployment due to single-fiber splicing. HFCL bridges this gap with IBR cables, where fibers are bonded at intervals. This ensures easier handling while retaining the speed advantage of ribbon splicing.

-

Cable Handling:

Avoid bending or twisting the cable too much. Each cable has a bend radius – the minimum radius you can bend it without causing damage. Stick to it. -

Strip the Cable Properly:

Strip the outer jacket, buffer coating, and cladding without nicking the fiber core. Precision is crucial when you are dealing with fiber optic connectors. -

Clean the Fiber:

Use isopropyl alcohol and lint-free wipes to clean the fiber. Any residue can lead to signal loss.

Connector Installation: The Heart of the Process

Installing the fiber optic connectors correctly is crucial for optimal performance.

-

Cleaving the Fiber:

Use a high-quality cleaver to ensure a clean, precise end face. The cleave should be perpendicular to the fiber axis. -

Fiber Insertion:

Insert the cleaved fiber into the connector ferrule carefully, ensuring it’s fully seated. Imagine threading a needle – precision is key. -

Epoxy or Mechanical:

Depending on the connector type, you’ll use either an epoxy method or a mechanical method to secure the fiber. Follow the manufacturer’s instructions in the letter. -

- • Epoxy Method: Mix and apply the epoxy correctly, avoiding air bubbles. Let it cure completely.

- • Mechanical Method: Ensure the fiber is properly aligned and secured with the mechanical crimp or clamp.

Polishing: The Finishing Touch

Polishing is like buffing a car – it makes all the difference in performance and appearance.

-

Polish the Connector:

After the epoxy has cured, polish the connector end face using the appropriate polishing film and method (hand polishing or machine polishing). -

Inspect the Polish:

Use a fiber inspection microscope to check for scratches, pits, or other defects. The end face should be smooth and clean.

Testing and Verification: Trust but Verify

Testing ensures everything is working as it should.

-

Visual Inspection:

Inspect the fiber optic connectors’ end face with a microscope to ensure it’s clean and properly polished. -

Optical Loss Testing:

Use an Optical Loss Test Set (OLTS) to measure insertion loss and return loss, ensuring the connector meets the required specifications. Aim for the lowest loss possible. -

Document Results:

Keep a record of test results for future reference and quality control. This is your fiber optic installation diary.

Maintenance Tips: Keeping It Clean

Just like any high-performance machine, fiber optics need regular maintenance.

-

Regular Cleaning:

Keep fiber optic connectors clean and free from dust and contaminants using fiber optic cleaning kits. -

Proper Storage:

Store connectors and cables in a dust-free environment with protective caps in place. -

Routine Inspections:

Periodically inspect installed connectors for any signs of wear, damage, or contamination.

Wrap Up

Mastering the installation of fiber optic connectors isn't just about following steps – it’s about understanding the importance of each step and how it impacts the whole system. By preparing thoroughly and testing rigorously, you ensure that your fiber optic connections will be reliable and efficient. Whether you’re working in a cutting-edge data center or a small office network, these tips will help you achieve top-notch results.