What’s Inside a Fiber Distribution Box? Let’s Break It Down!

Fiber Distribution Boxes (FDBs) are critical components in modern telecommunications infrastructure, particularly in fiber optic networks. They function as junction points that manage, protect, terminate, and distribute fiber optic cables, ensuring efficient data transmission between different network elements. FDBs play a pivotal role in maintaining signal integrity over long distances, offering a centralized location for splicing, connecting, and branching fiber optic links. Their presence simplifies network management, minimizes signal loss, and safeguards fiber connections from environmental hazards.

Basic Components of a Fiber Distribution Box

A typical Fiber Distribution Box includes several key components:

- • Cable Inlet and Outlet: These are specifically designed entry and exit points for fiber cables, ensuring secure passage while maintaining environmental protection. Equipped with gaskets or seals, they provide waterproof and dustproof capabilities, preventing external elements like moisture and debris from damaging the cables.

- • Splice Tray: This compartment is designed for fiber splicing and storage. It features slots or holders that secure spliced fibers, protecting them from bending, physical damage, or external stress. Clear labelling options are also included for easy identification and maintenance.

- • Adaptors and Connectors: These components facilitate connections between incoming and outgoing fiber cables and network devices. Adaptors are mounted on the panel to hold connectors in place, ensuring precise alignment and minimal signal loss. Common types include SC, LC, and MPO adapters, catering to various application needs.

- • Cable Management Systems: These cable management systems consist of guides, clips, or brackets that organize and route cables within the box. They help minimize cable tangling, bending, or overstressing, ensuring optimal signal integrity. Effective cable management reduces maintenance time and enhances overall network reliability.

- • Enclosure: The enclosure is the outer shell of the FDB, typically made from durable materials such as ABS, SMC, or metal. It shields internal components from harsh environmental conditions, such as UV rays, rain, and extreme temperatures. Many enclosures feature secure locking mechanisms for tamper resistance, providing both physical and environmental protection.

Key Benefits of Fiber Distribution Boxes

1. Enhanced Network Reliability

FDBs are specifically designed to safeguard delicate fiber optic connections from environmental and physical damage. By protecting splices, connectors, and cables from dust, moisture, UV exposure, and accidental impact, they ensure uninterrupted and high-quality signal transmission. This robust protection minimizes the likelihood of network outages and maintains consistent performance even in challenging environments.2. Scalability

FDBs are built with futureproofing in mind, enabling easy upgrades and network expansions. They can accommodate additional fibers, connectors, and splices without significant redesigns or replacements. This makes them ideal for networks that anticipate growth, as they provide the flexibility to adapt to increased capacity demands with minimal disruption.3. Cost Efficiency

By organizing and protecting fiber connections, FDBs simplify both the installation process and ongoing maintenance. Clear labelling, accessible splice trays, and efficient cable management reduce labour time and associated costs. Additionally, their durability and protection reduce the risk of costly repairs or replacements, leading to long-term savings for network operators.4. Flexibility

FDBs are compatible with a wide range of fiber optic connectors, such as SC, LC, and MPO, and can support both single-mode and multimode fibers. This adaptability makes them suitable for diverse applications, from residential networks/multi-dwelling units (MDUs) to large-scale data centers. Their versatile design allows seamless integration with various deployment scenarios, such as aerial, pole-mounted, or wall-mounted installations.

The Evolution of Fiber Distribution Boxes

FDBs have undergone remarkable advancements over the years, reflecting the evolving needs of modern telecom networks:

-

• Design Innovations

Originally simple enclosures meant to house fiber connections, FDBs have evolved into modular and compact systems that maximize space utilization. Modern designs prioritize ease of access for technicians, featuring removable panels, stackable splice trays, and intuitive layouts for faster installation and maintenance. This shift has not only improved operational efficiency but also enabled seamless integration into various deployment scenarios. -

• Advanced Materials

Early FDBs were often made of metal, which, while durable, was prone to corrosion and added significant weight. The introduction of high-grade plastics like ABS and PC has revolutionized FDB construction. These materials are lightweight, and highly resistant to UV radiation, moisture, and extreme temperatures, making them ideal for outdoor installations. Additionally, they contribute to longer service life and lower transportation and handling costs. Plastic variants are also known as Fiber Access Terminal (FAT) boxes. -

• Enhanced Functionality

Today's FDBs go beyond basic fiber protection. They now include built-in splitters for efficient signal distribution, optimized cable management systems to reduce stress on fibers, and advanced sealing techniques to prevent the ingress of water and dust, even in harsh environments. These enhancements have expanded their utility, enabling use in high-density networks and rugged conditions.

Types of Fiber Distribution Boxes

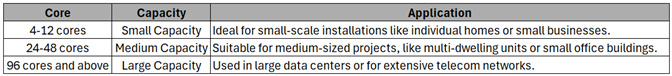

Classification by Capacity

Classification by Mounting Type

-

• Wall-Mounted:

Common in residential and small office environments where space is limited. -

• Pole-Mounted:

Used for outdoor applications, particularly in rural or urban settings where cables are strung overhead. -

• Rack-Mounted:

Essential for data centers and large telecom installations where equipment is centralized.

Key Features of Fiber Distribution Boxes

-

1. High Protection Level

FDBs are designed to withstand challenging environmental conditions, with outdoor models often rated IP55 or higher. This rating ensures they are resistant to dust ingress and water sprays, providing robust protection for internal components. Higher IP-rated models can even endure extreme conditions like heavy rainfall or harsh industrial environments, making them ideal for outdoor deployments. -

2. Modular Design

The modular design of FDBs allows for seamless adaptation and expansion as network requirements grow. Technicians can easily add splice trays, adapters, or even splitters without needing significant structural modifications. This flexibility ensures that the FDB remains a future-proof solution, accommodating both current and future needs with minimal effort. -

3. Cable Management

Effective cable management systems in FDBs help organize and secure cables, reducing the risk of tangling or damage. Features like clips, guides, and routing pathways maintain proper bend radii, minimizing signal attenuation. This organized layout simplifies troubleshooting and maintenance, saving both time and operational costs. -

4. Compatibility

FDBs are engineered to support a wide range of fiber optic connectors, including Square Connector or Standard Connector (SC), Lucent Connector (LC), and Ferrule Connector (FC) types. This versatility makes them suitable for diverse applications, from residential setups to enterprise networks and industrial deployments. Compatibility with single-mode and multimode fibers further enhances their adaptability.

Applications of Fiber Distribution Boxes

1. FTTH (Fiber to the Home)

FDBs are integral to FTTH deployments, where they connect the fiber optic backbone to individual residences. By housing and organizing fiber splices, adapters, and splitters, they enable reliable high-speed internet access for end-users. Their compact design and ability to withstand outdoor conditions make them ideal for installation in residential neighborhoods, ensuring seamless connectivity for modern smart home applications.-

2. Data Centers

In data centers, FDBs act as a centralized point for managing fiber connections between servers, storage devices, and networking equipment. They organize and protect high-density fiber connections, ensuring optimal performance and minimal signal loss. By supporting rapid scalability and easy maintenance, FDBs play a key role in enabling high-speed, intra-data center communication required for cloud computing and big data applications. -

3. Telecommunication Base Stations

FDBs are crucial at telecommunication base stations, where they connect fiber from the backhaul network to the base station infrastructure. They support the reliable transmission of data, voice, and video, forming the backbone of mobile network operations, including 4G and 5G networks. Their robust build and environmental protection features make them suitable for remote and challenging locations.

Best Installation Practices for Fiber Distribution Boxes

• Environmental Assessment:

Choose the right type (indoor vs. outdoor) based on the installation environment.-

• Cable Management:

Ensure cables are neatly organized to prevent bending beyond the recommended radius. -

• Accessibility:

Install in locations that allow easy access for maintenance without disrupting service. -

• Weatherproofing:

For outdoor installations, ensure all seals and gaskets are intact to protect against elements.

Future Trends in Fiber Distribution Boxes

-

• Integration with Smart Technologies:

FDBs might incorporate sensors for real-time monitoring of network health. -

• Material Innovation:

Use of new materials like hollow-core fibers for even greater environmental resistance and lower signal loss. -

• Automation in Maintenance:

Developments in robotic maintenance for hard-to-reach or hazardous environments.

Conclusion

Fiber Distribution Boxes are indispensable in the realm of fiber optic networking, providing not just connectivity but also protection and management of one of the most critical aspects of modern telecommunications. Their evolution reflects the industry's push towards more reliable, scalable, and efficient networks. As technology advances, FDBs will continue to adapt, ensuring they meet the growing demands of data transmission and connectivity.