Unfavorable working conditions, manual work, extreme heat, dust, darkness, and discomfort- a general picture of what people perceive of the mining industry. However, this perception is all about to change, as technological advancements pave the way for automation and empower workers. The potential for automation in mining is immense, evident from the projected growth of the smart mining market. According to Mordor Intelligence, this market is expected to triple by 2025, with 25% of mines adopting autonomous operations by then. One crucial factor that will drive the widespread adoption of automation in mining is the availability of a high-speed network such as 5G. Recent reports indicate that the integration of 5G in the mining industry will experience exponential growth in the coming years.

In 2023, the industry was valued at $2.15 billion, but by 2029, it is projected to reach an impressive value of $12.75 billion, representing a remarkable compound annual growth rate (CAGR) of 34.55% during the forecasted period.

These statistics highlight a transformative journey for an industry that has been conservative when it comes to the adoption of new methods and technologies and has relied heavily on manual labor. As advancements continue, the industry is witnessing improvements in both safety and efficiency in mining operations. Tasks that were once carried out manually are now being automated, mitigating the risks associated with human labor and offering a glimpse into a future where mining becomes a safer and more streamlined process. However, the process is not going to be as easy as it seems, there are a lot of challenges that the mining industry is facing currently and some of them are as follows:

Challenges in the mining industry:

Safe or not- The Everyday Concern

Did you know that mining is among the top 10 most dangerous professions? (Source- US Bureau of Labor Statistics) Thermal stress, UV exposure, chemical hazards, dust inhalation, and loud noises are some of the common health risks associated with working in the mining industry.

Solution: While strict safety legislation and protocol are being implemented, there’s still a need to come up with solutions that can help drop the fatality rate over time. Reports believe that with automation this risk of health hazards can be reduced. According to a white paper by Accenture & the World Economic Forum, up to 1,000 deaths and 44,000 injuries can be prevented over the next decade. This would mean reducing fatalities by 10%, and injuries by 20%.

Environmental Impact- Threat to future generations

Globally, mining operations contribute to approximately 4 to 7 percent of total greenhouse gas (GHG) emissions. (Source- Mckinsey) This is an issue that needs to be addressed not because there is pressure from climate activists but because of our duty toward protecting the environment and creating a safe space for future generations to come. Therefore, there is a need for sustainable solutions and thanks to technology and automation, significant reductions in CO2 emissions and energy consumption can be achieved.

Solution: A recent report suggests that the early adoption of technologies enabling autonomous operations could lead to an annual decrease in carbon emissions by 25%. For instance, robots and autonomous vehicles are compact in design compared to traditional manufacturing machines, resulting in lower energy requirements. Furthermore, their operation is much cleaner as they do not emit pollutants such as fumes or smoke, unlike other machinery. These vehicles can be powered by electricity or utilize hybrid systems, reducing dependence on fossil fuels.

Need Skills: Embracing technological changes is a task

Adapting to technological changes can be a daunting task, especially for workers in the mining industry who have spent most of their lives engaged in manual labor. The introduction of robots, unmanned vehicles, and automated processes can seem overwhelming to them. This lack of familiarity with new technologies poses a significant challenge in the mining sector, leading to a shortage of adequately skilled staff capable of operating in a digital mining environment. However, 5G in mining brings a lot of hope for the workers.

Solution: To address this challenge, it is important to approach the situation empathetically. Workers can be provided with comprehensive tutorials and step-by-step instructional videos to help them become familiar with the technology and new devices. Utilizing augmented reality (AR), virtual reality (VR), and other online media platforms can facilitate the learning process, making it more accessible and engaging for individuals who may not have a strong background in technology. By embracing these methods, we can empower workers to acquire the necessary skills and confidently navigate the digital mining landscape.

Connecting People: Home Away from Home

Working in harsh and isolated conditions can have a profound impact on a person's mental well-being. For individuals employed in mines, being away from home for extended periods can lead to feelings of loneliness and isolation. It is crucial to address these challenges in the mining industry and provide them with a means to connect with their loved ones, celebrate important life events, and enhance their overall productivity.

Solution: To tackle this issue, some mining companies have taken the initiative to offer free telephony and WiFi services on-site. However, there is still a need to improve communication options during their time away. One promising solution for the future involves the utilization of holographic imagery and virtual or augmented reality technologies. Just imagine what positive impact will it have on the workers who can now see their loved ones daily, share a meal with them, and communicate their feelings with them, even when they are thousands of kilometers apart!

5G in mining- Why it is significant for the industry that is headed toward AUTOMATION?

5G in mining holds immense potential as it makes automation easier to implement, facilitates the adoption of new technology, and provides crucial support that is much required for this digital revolution in mining.

Regardless of the technologies employed, the success of smart mining relies heavily on reliable wireless connectivity, with cellular networks serving as the essential foundation. Mining organizations need network infrastructures capable of handling the massive amount of data generated by vehicles, equipment, and workers. 5G-enabled private cellular networks are ideally positioned to fulfill all the connectivity requirements.

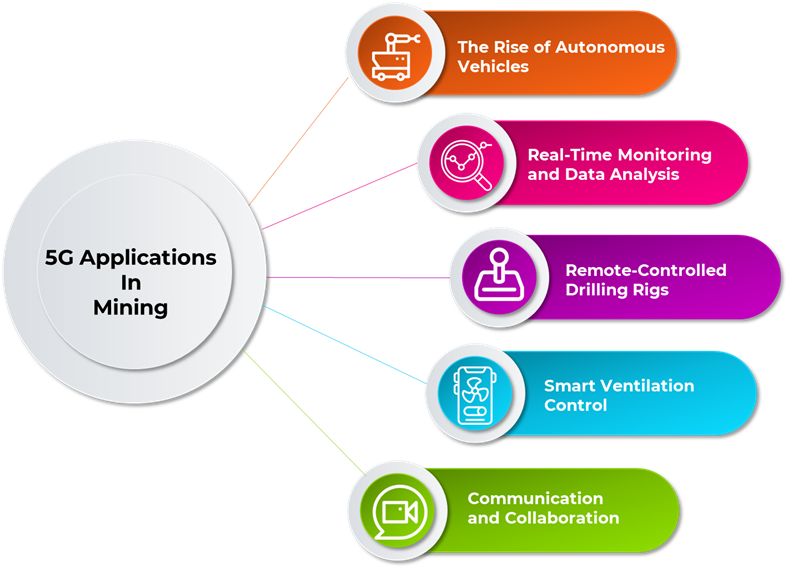

Applications of 5G in Mining

Hands Off: The Rise of Autonomous Vehicles

Autonomous vehicles are by far the most advanced innovations in the mining industry that has the potential to improve the safety and efficiency of the workers in the mines. However, the main game player here will be the high bandwidth and low latency provided by 5G. Autonomous vehicles and equipment can operate efficiently and safely in mining environments with a high-speed network. With a robust network infrastructure, mining companies can deploy autonomous vehicles, unmanned drones, and other remote-controlled machinery to operate in hazardous or inaccessible areas. This improves worker safety and increases productivity by reducing manual labor requirements.

Dig Deeper: Real-Time Monitoring and Data Analysis

Another major application of 5G in mining is real-time condition monitoring that optimizes uptime and improves safety in the mines. Mining operations generate vast amounts of data, including information from sensors, equipment, and geological surveys. Analyzing large datasets in real-time becomes more feasible with high-speed networks. High-speed networks enable real-time data monitoring, allowing mining companies to collect, process, and analyze data quickly. This can help identify potential safety hazards, predict equipment failures, optimize operational efficiency, and implement preventive maintenance strategies.

Add Thrill to Drill: Remote-Controlled Drilling Rigs

Remote control drilling is faster than manual methods, resulting in an impressive 60% boost in productivity (Source- Oxford University's "Technology at Work). Due to the necessity of multiple connections on a single vehicle and the high bandwidth demands for video streaming, strong network connectivity is consistently required for remote drilling. 5G in mining emerges as an ideal connectivity solution for enabling remote drilling due to its compatibility with licensed and unlicensed spectrum, high uplink speed, and very low latency.

Smart Ventilation Control: Automated Ventilation Powered by 5G

Automation has become pervasive in all mining operations areas, including ventilation systems. The implementation of automatic ventilation technology has brought about significant benefits in terms of both control and monitoring of various components such as fans, louvers, and ventilation doors. Automated ventilation systems are reliant on a secure connection with high bandwidth and low latency for fast and real-time data transmission. By enabling real-time monitoring, this automated system enhances ventilation efficiency, resulting in cost reduction. Moreover, it creates a more favorable and hospitable working environment for miners.

Connection Matters: Communication and Collaboration

In mining operations, a diverse range of professionals, such as geologists, engineers, managers, and contractors, play integral roles. The smooth flow of communication and collaboration among these teams and locations is greatly facilitated by high-speed networks. These networks enable seamless video conferencing, file sharing, and real-time communication tools, which enhance the efficiency of decision-making, project management, and troubleshooting. Additionally, miners must maintain connections with their loved ones. With the advent of 5G technology or high-speed network connections, uninterrupted video calls are made possible, allowing miners to feel close to home even while being physically distant.

Final Words:

“More the automation, the lesser will be the environmental impact.”

The integration of 5G in mining operations is highly consequential, particularly with the increasing automation and need for real-time monitoring. This development holds immense significance not only for the organizations involved but also for the environment and the well-being of workers, as it enhances their safety.

However, achieving these positive changes relies heavily on the availability of fast, reliable, and secure connectivity that can only be provided by 5G networks. The widespread adoption of high-speed networks has the potential to address the ongoing challenges in the mining industry and completely transform the way mining is approached from its very core. By embracing the potential of 5G technology, the mining industry can pave the way for a future that is both technologically advanced and environmentally responsible, fostering a better and safer world for all involved.